International Journal of Applied Chemistry.

ISSN 0973-1792 Volume 13, Number 1 (2017) pp. 29-52

© Research India Publications

http://www.ripublication.com

Fly ash in India: Generation vis-à-vis Utilization and

Global perspective

Surabhi

Department of Applied Chemistry, Pillai College of Engineering,

University of Mumbai, Mumbai, 410206, India.

Abstract

Global energy demand is set to increase by almost 50% in the period 2016 to

2040. Much of this growth will continue to be concentrated in the developing

world, primarily China and India, as industrialization, population growth and

the unprecedented expansion of the middle class will propel the need for

energy in general and coal, in particular. The Indian coal is of low grade

having high ash content of the order of 30 - 45% producing large quantity of

fly ash at coal/lignite based thermal power stations in the country. The

management of fly ash has been troublesome in view of its disposal because of

its potential of causing pollution of air and water. In this paper, the nature of

Indian fly-ash and its various utilizations have been described. In the past

decade, there has been tremendous increase in the generation of fly-ash since

more than 70% of country’s demand for electricity is met by coal-based thermal

power plants. At present, India produces approximately 180 million-tons of

fly-ash. The disposal of such huge quantity of ash is a serious issue.This paper

also gives an overview of global scenario of fly ash generation and its utilization

apart from India.

Keywords: Fly ash; Coal; Cement; Concrete; MoEFCC; Thermal Power Plants;

Generation; Energy; Utilisation

30 Surabhi

INTRODUCTION

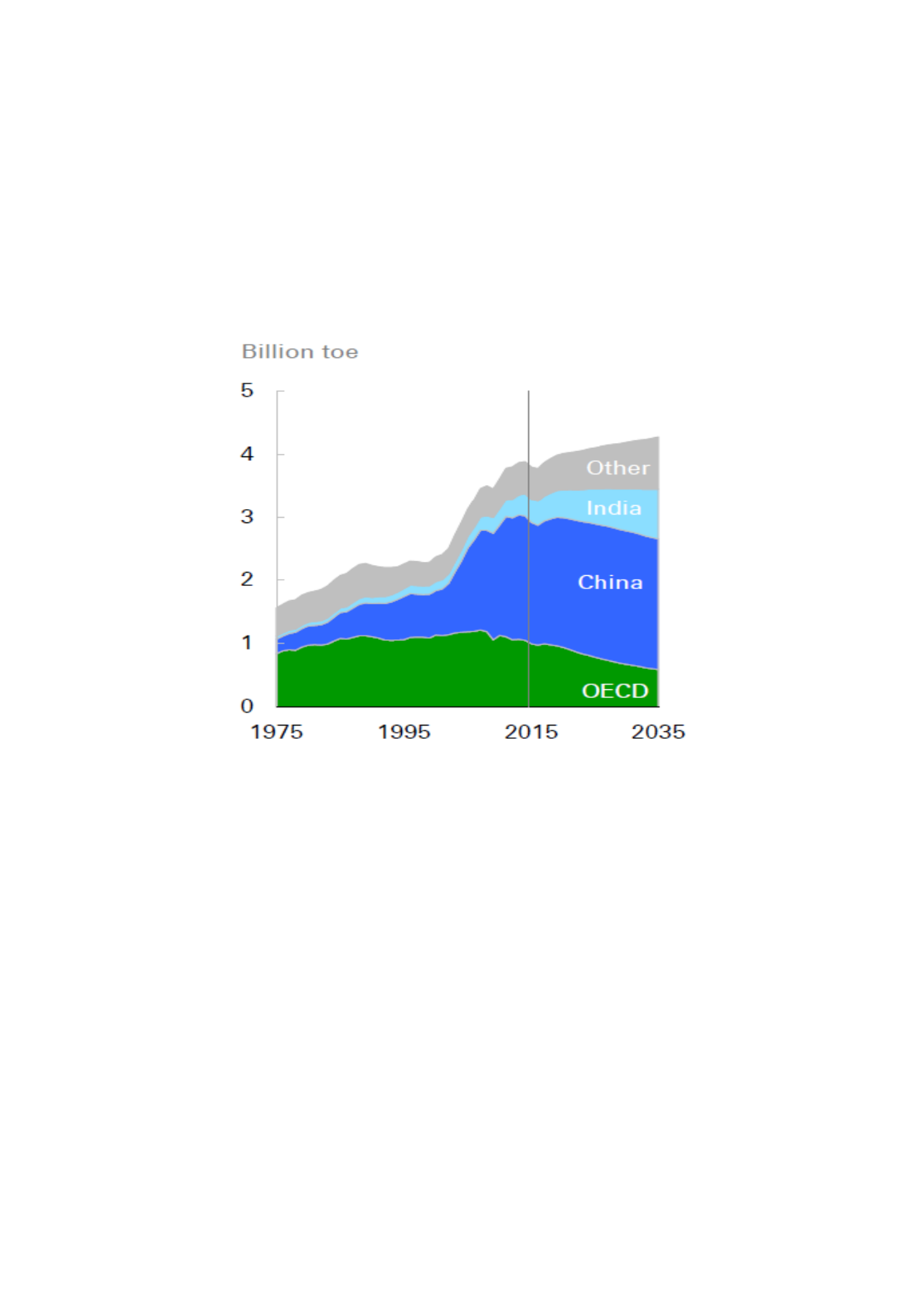

As an essential ingredient for growth and development, energy has become the

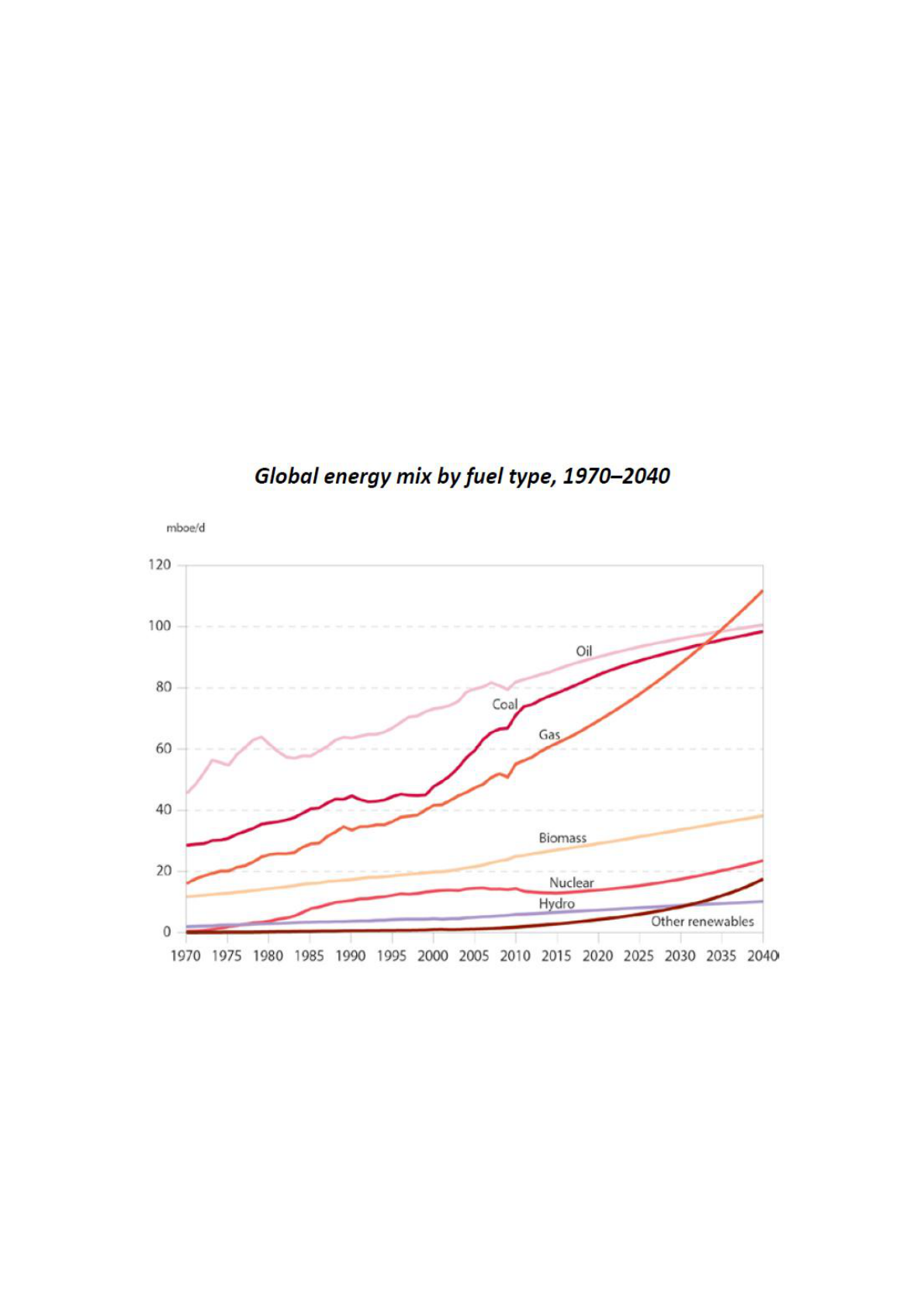

driving force of the modern economy. Since the 1970s, traditional fossil fuels have

been the dominant energy source (Figure 1). Oil, the leading energy source in 1970,

made up 43% of total energy demand, while the shares of coal and natural gas were at

27% and 15%, respectively. By 2016, however, these figures had shifted somewhat.

The share of natural gas had increased to 22%, while that of oil had dropped to 32%.

However, Coal’s share remained roughly dominant over the period.

Figure 1: Global Energy mix by fuel type, 1970- 2040 [1]

Coal being abundantly available worldwide, therefore, has been major source of

energy and expected to remain so in future. In order to produce energy, pulverized

coal is generally burned. During combustion, the volatile matter and carbon is burn

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 31

off and the coal impurities such as clays, shale, quartz, feldspar etc. mostly fuse and

remain in suspension[2]. These fused particles are passed along with flue gas. As the

flue gas approaches the low temperature zone, the fused substances coagulate to form

mainly spherical particles which are called fly ash. The remaining matter which

agglomerate and settle down at the bottom of furnace are called bottom ash. The

distribution of bottom ash and ESP ash is 20% and 80% respectively.

Fly ash was used to build Roman Colosseum, a 2000 year old structure which still

stands the test of time; is a classic example to know its existence. People used ash

generated from volcanoes in the construction of many roman structures. Volcanic ash

is the same as fly ash, the only difference is fly ash is generated artificially through

coal.

Fly ash is defined as per Cement & concrete terminology[3], “Finely divided residue

resulting from the combustion of ground or powdered coal which is transported from

the fire box through the boiler by flue gases”.

Fly ash is captured by mechanical separators, electrostatic precipitators or bag fillers.

ASTM C-618[4] categorizes coal combustion fly ash into two classes- Class F &

Class C. The Class F fly ash are normally generated due to combustion of anthracite

or bituminous coal and Class C is obtained by the burning of lignite or

sub-bituminous coal combustion.Class C fly ash possess CaO in excess (10-40%)

while Class F contains CaO less than 10%. Due to higher CaO content, Class C fly

ash participate both in cementitious and pozzolanic reaction whereas class F fly ashes

mostly contribute in pozzolanic reaction during hydration process.

Apart from chemical properties, physical properties of fly ash also play an important

role in cement. Physical properties of fly ash improve the microstructure and rheology

of concrete. Fly ash cannot react with water. It requires free lime which is formed on

hydration of Portland cement. This enables to trigger off its pozzolanic effect. It leads

to a longer life for concrete structure. For instance, Ghatghar Dam in India is a classic

example which is constructed using fly ash and the tallest building in the world - Burj

Khalifa in Dubai is another structure constructed using fly ash.

The benefits of fly ash include: delay the heat of hydration which helps in reduction

of thermal cracks in concrete; improves the workability of concrete and enhances the

life of structures and buildings among others [5]. The fly ash market are growing day

by day because of urbanization in emerging economies and increasing constructional

activities internationally. The beneficial properties of fly ash have attracted the

32 Surabhi

construction sector worldwide as fly ash has best suited the requirement for various

infrastructure projects.

The durability of concrete is directly affected by its permeability. Permeability is

defined as the property that governs the rate of flow of a fluid into a porous solid.The

major reasons for permeability of concrete are nature of hardened cement and

inter-connectivity of pores in the cement [6]. Poor quality of fly ash is responsible for

high permeability of concrete which is a major threat for the demand and growth of

global fly ash market.

In addition, fly ash has been proven to be the green building material due to

environmental benefits that it offers. Hence, the global fly ash market is anticipated to

experience high demand in the market during the forecast period from 2016-2022.

GLOBAL SCENARIO

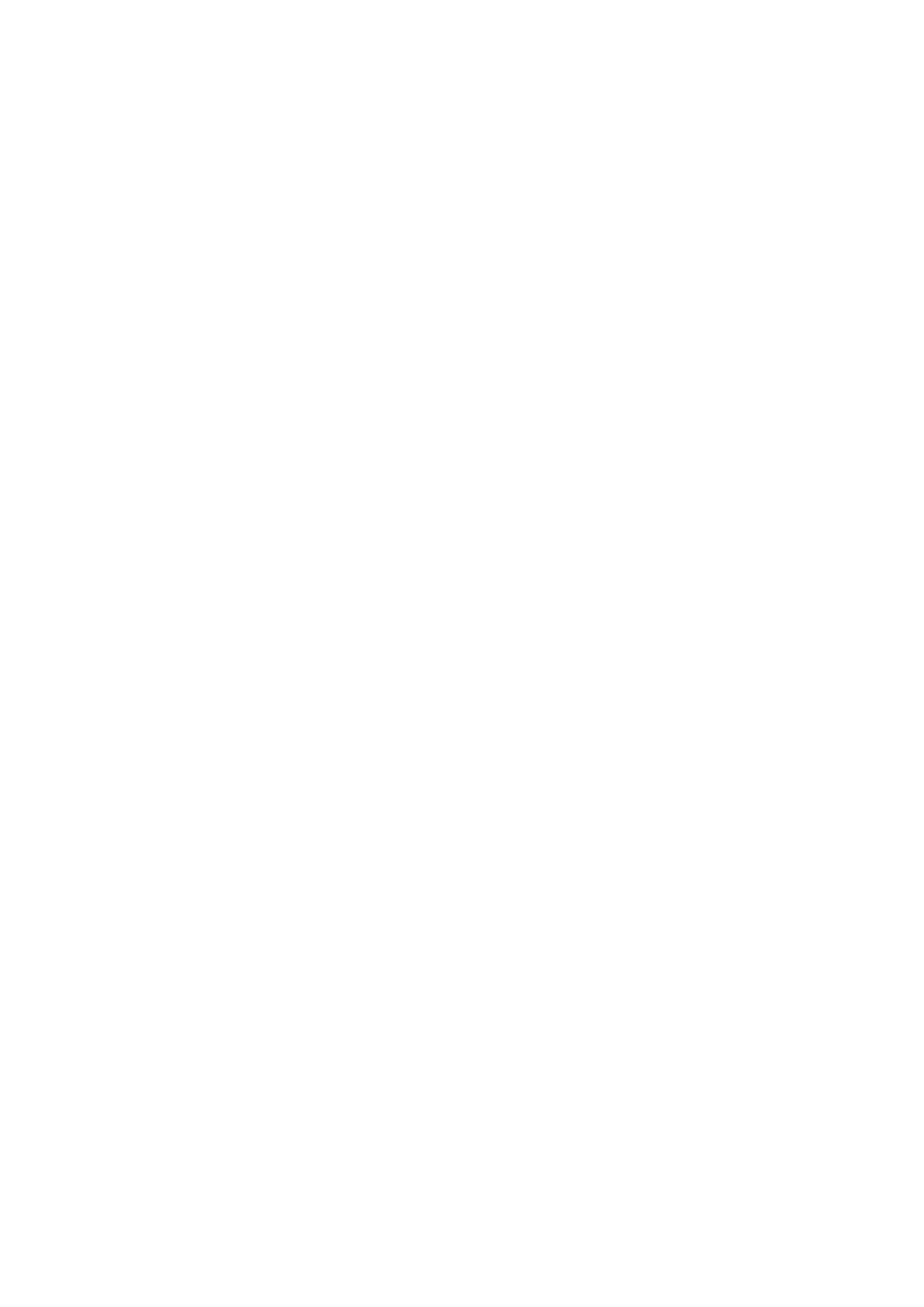

Coal is the most abundant fossil fuel on the planet. It is a relatively cheap fuel, with

some of the largest deposits in regions that are relatively stable politically, such as

China, India and the United States. In last half century, coal has been a dominant

player in energy generation world-wide (Figure 2) and is projected to maintain it’s

dominance in decades to come.

Figure 2: Fuel-mix in global generation of energy [1]

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 33

China remains the world’s largest coal market, consuming almost half of global coal

supplies in 2035 (Figure 3). India shows the largest growth in coal consumption (435

M ton), overtaking the US to become the world’s second biggest consumer of coal.

Over two-thirds of India’s increased coal demand feeds into the power sector.

Figure 3: Regional break-up of Coal consumption [1]

During the last few decades, there has been a dramatic increase in coal ash production

in the world due to increased amounts of energy being generated by coal-fired power

plants. A number of researchers [7,8,9], have compiled extensive data on production

and utilization of coal ash in the world. The countries which are marching toward

rapid industrialization, such as China, and India, are showing increasing demand for

coal.

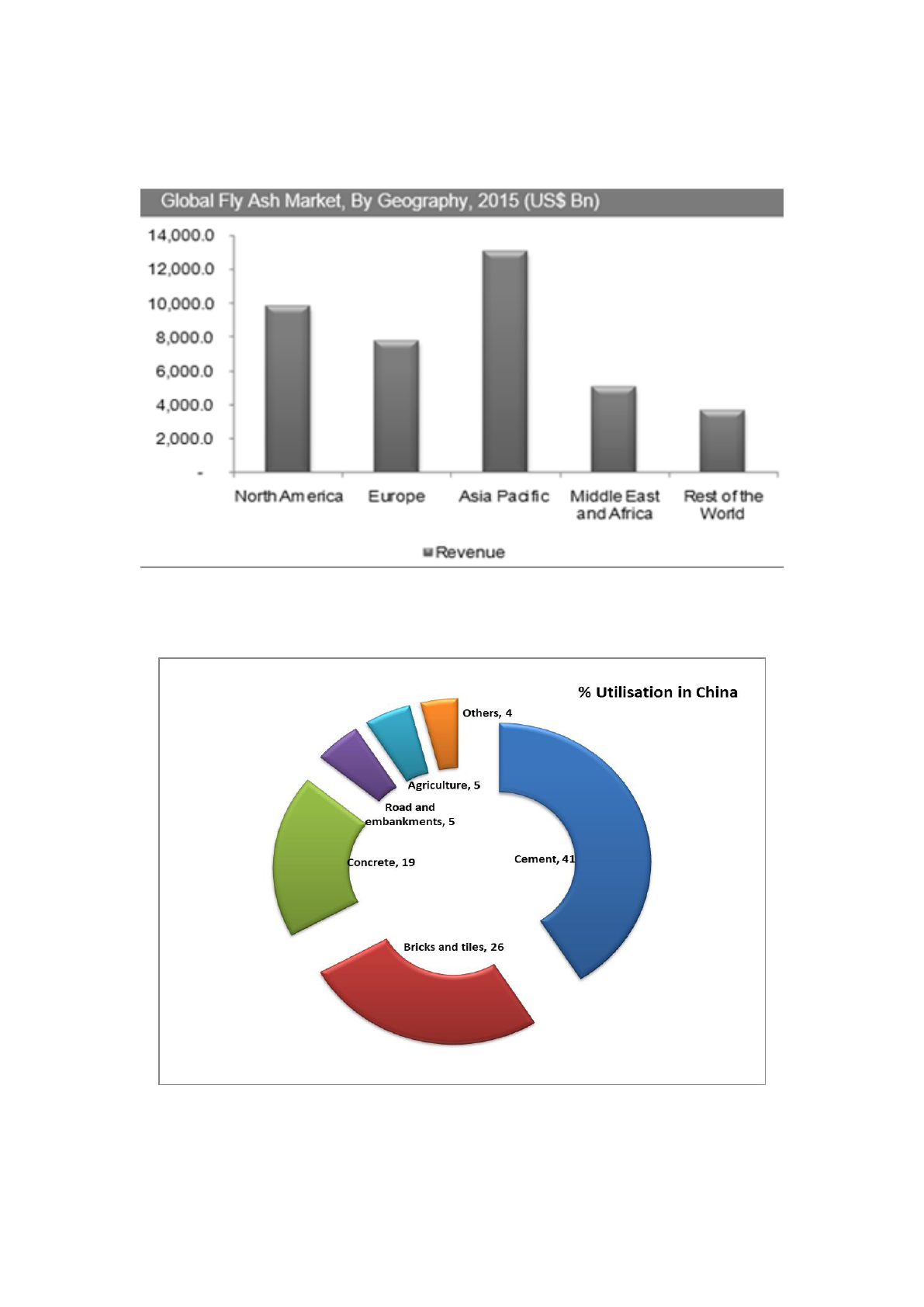

Asia Pacific accounted for larger share of global fly ash market in 2015. Growing

urbanization in and growing population in the region have led to increasing demand

for constructional activities. Improvement in the road constructions and steps adopted

for ease in transport through building highways, etc has also led to high demand for

34 Surabhi

fly ash thereby promoting growth of global fly ash market. Increasing demand from

building and construction industry in North America is also expected to boost growth

of fly ash market. Europe is projected to fuel demand for fly ash due to environmental

measures adopted in the region. Middle East and Africa and Rest of the World

demonstrated steady growth for fly ash in the year 2015 but are anticipated to

augment during the forecast period. Hence, fly ash market is expected to experience

strong demand from several countries to meet the needs of the constructional sector

worldwide.

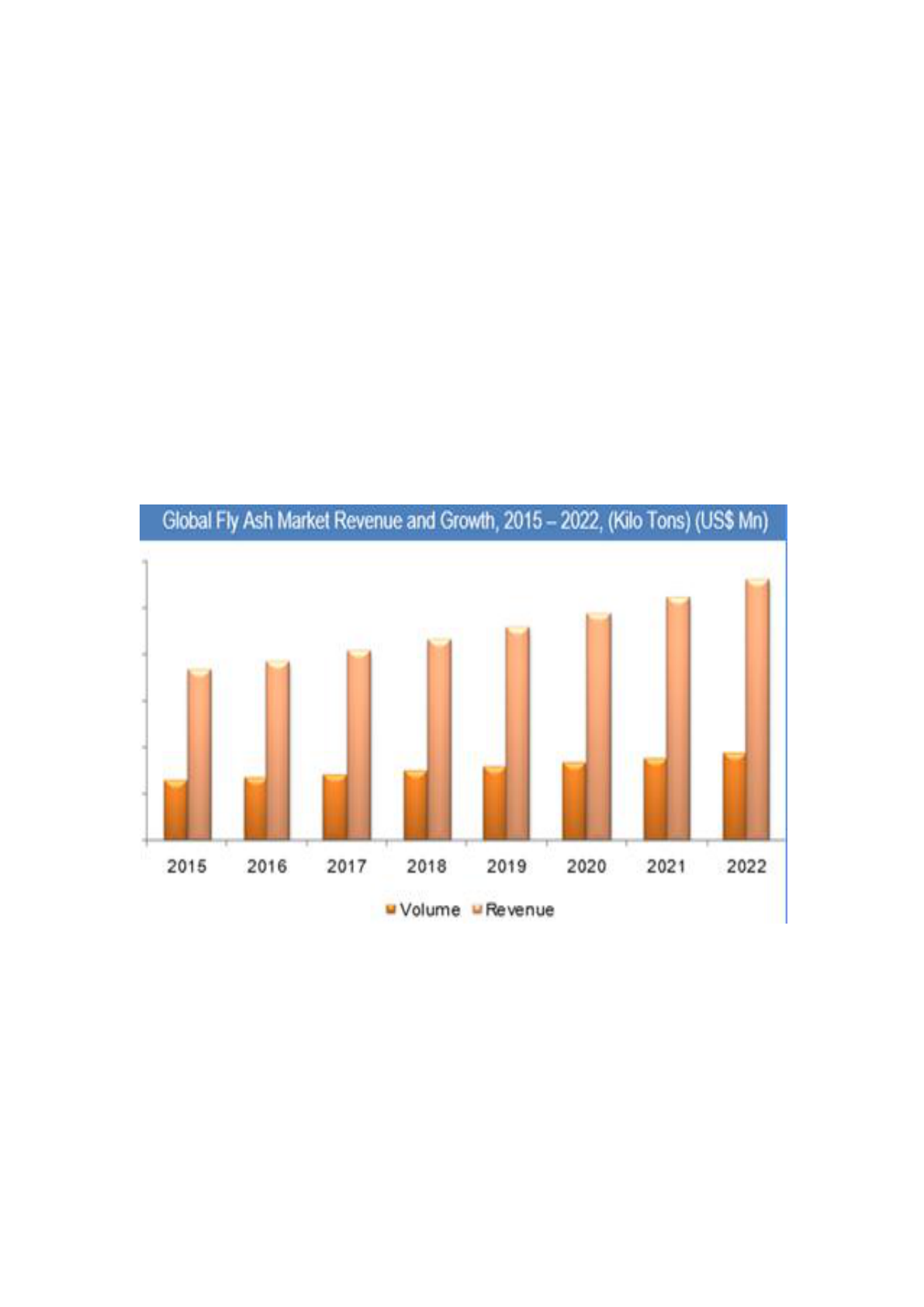

Fly Ash market was valued at US$ 39,548.1 Mn in 2015 and is expected to reach

US$ 64,761.9 Mn by 2022, growing at a CAGR of 7.3% during the forecast period

2016-2022 (Figure 4).

Figure 4: Global Fly Ash Market Revenue and Growth

Cement concrete technologies have been going through immense evolutionary

changes. Apart from factors such as strength, economy and durability are also playing

an important role globally. Initially, cement did not possess properties of strength and

durability, therefore, to make concrete durable and strong, cementious material such

as fly ash was started as a practice which is now used on a large scale worldwide.

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 35

Portland cement accounted for the largest share of global fly ash market in 2015 and

is expected to retain its position during the forecast period from 2016 to 2022.

Figure 5: Global Fly Ash market revenue by application ( USD Bn )

Portland cement was the leading end use application of fly ash in 2015, accounting for

more than 26% of market revenue. The benefits of fly ash make it an essential

element to be used in Portland cement, road constructions and fire bricks. Portland

cement is expected to retain its position in the near future due to the strong demand

from the construction industry globally. Growing preference for greener substitutes is

another major driving factor for global fly ash market as fly ash contributes to

maintain pollution free environment. Road constructions and fire bricks are also

expected to follow the growth patterns of Portland cement in terms of demand in the

near future because of urbanization. Fly ash in form of concrete and fire bricks has

proven to be the best concrete in term of strength. Decorative glass, agriculture and

other applications are also projected to show steady growth in the near future. Hence,

rising demand for fly ash from speckled industries is expected to offer growth

opportunities for fly ash during the forecast period from 2016 to 2022.

36 Surabhi

Figure 6: Global Fly Ash Market by Geography

Figure 7: Utilization of Fly Ash in China [10]

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 37

According to the annual report of China comprehensive resource utilization (2012)

released by the National Development and Reform Commission (NDRC) of China,

the coal fly ash generation and utilization were 540 and 367 million tonnes in 2011

respectively. The utilization rate reached 67.96%, higher than that for the US

(46.74%) and India(55.79%). Among the section of utilization, the top 3 were

cement(41%), brick and tiles (26%) and concrete (19%) (Figure 7).

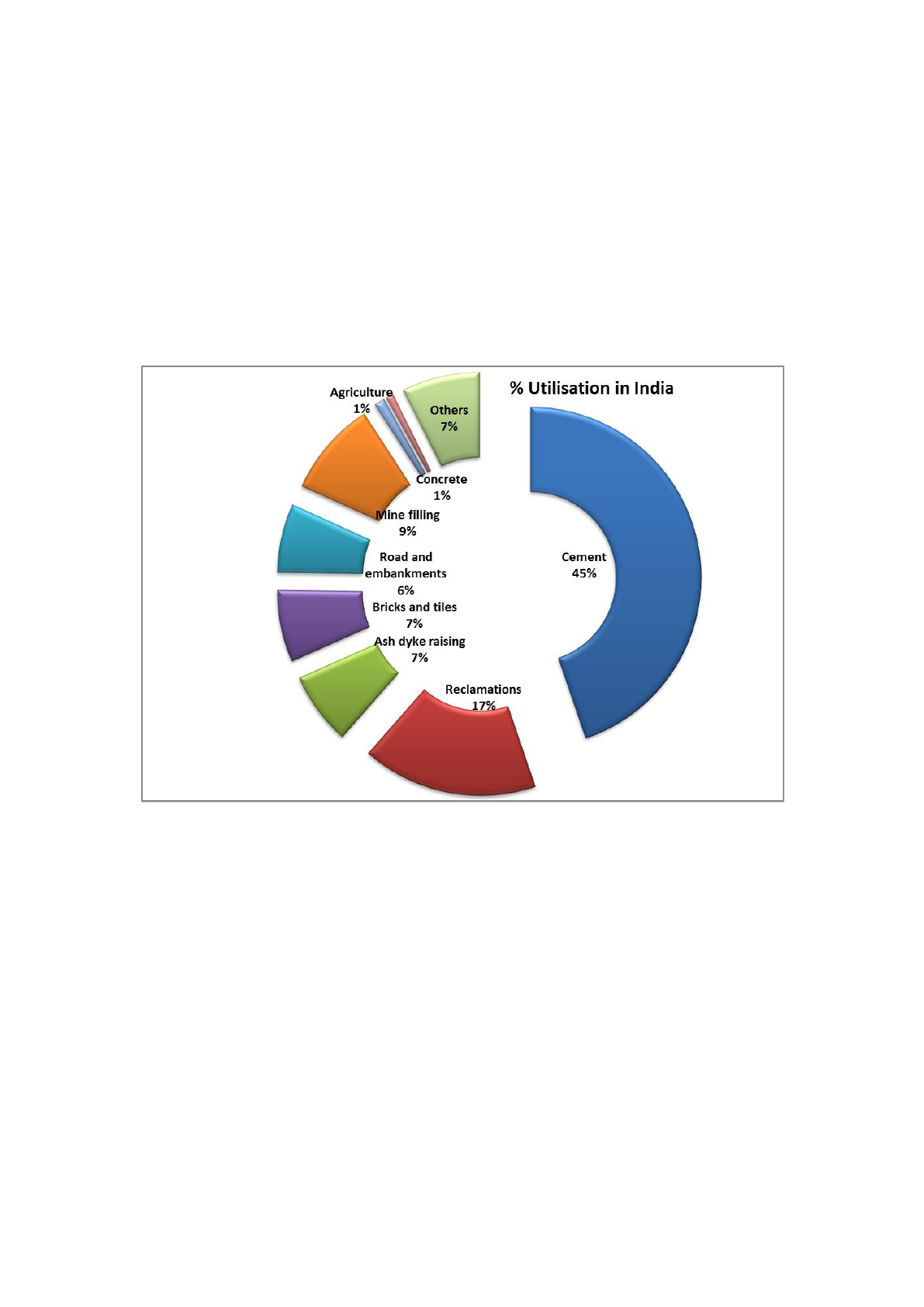

Figure 8: Utilization of Fly Ash in India [10]

The generation of fly ash in India has increased from 68.88 million tonnes in 1996–97

to 163.56 million tonnes in 2012–13, of which only 100.37million tonnes was

utilized. India has achieved a tremendous increase in its utilization from 9.63% in

1996–97 to 61.37% in 2012–13. However, nearly 40% of the ash is still unused.

38 Surabhi

ASH GENERATION & UTILIZATION IN INDIA

Coal/Lignite based Thermal Power Generation has been the backbone of power

capacity addition in the country. Indian coal is of low grade with ash content of the

order of 30-45 % in comparison to imported coals which have low ash content of the

order of 10-15%. Several no. of Coal/Lignite based thermal power plant is setup for

providing electric power to rapidly growing industrial as well as agriculture sectors.

In which 70 percent of the electricity generated is from coal based thermal plant. In

order to achieve the India economic growth of 8-9 percent, the country’s total coal

demand, has been forecast to increase ~ 730 Million tons in 2010-11 to ~2000 Million

tons in 2031-32 of this approx. 75 percent of this coal would go thermal power plant

[11].

Large quantity of ash is, thus being generated at coal/lignite based thermal Power

Stations in the country, which not only requires large area of precious land for its

disposal but is also one of the sources of pollution of both air and water.

Following graph is showing the production of fly ash samples from coal year wise in

India.

Figure 9: Generation of Fly Ash in India

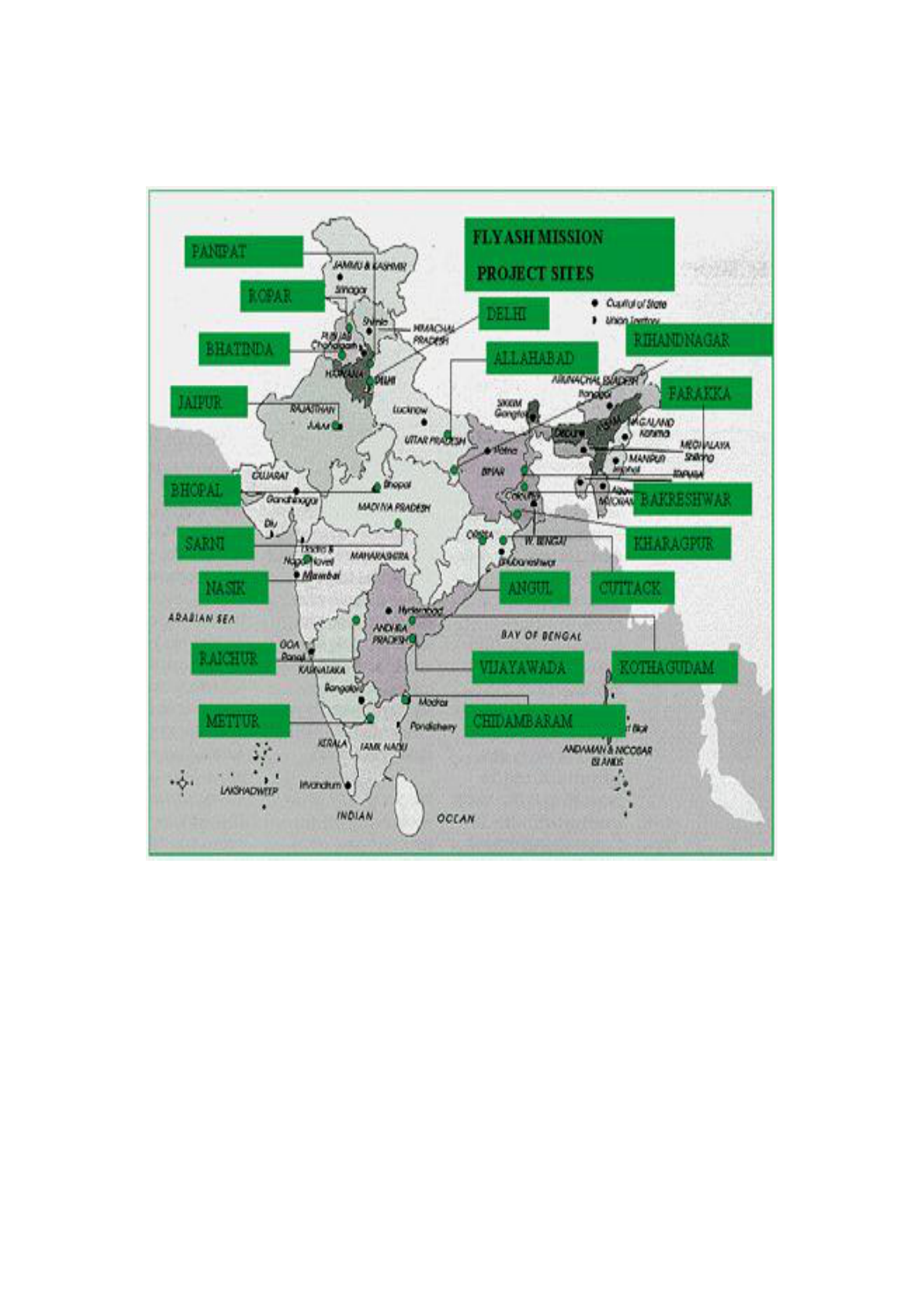

To reduce the problem caused by production of fly ash, it is now mandatory to use fly

ash based products in all government schemes or programmes. Figure 10 shows the

fly ash mission project sites.

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 39

Figure 10: Fly ash Mission Project Sites [12]

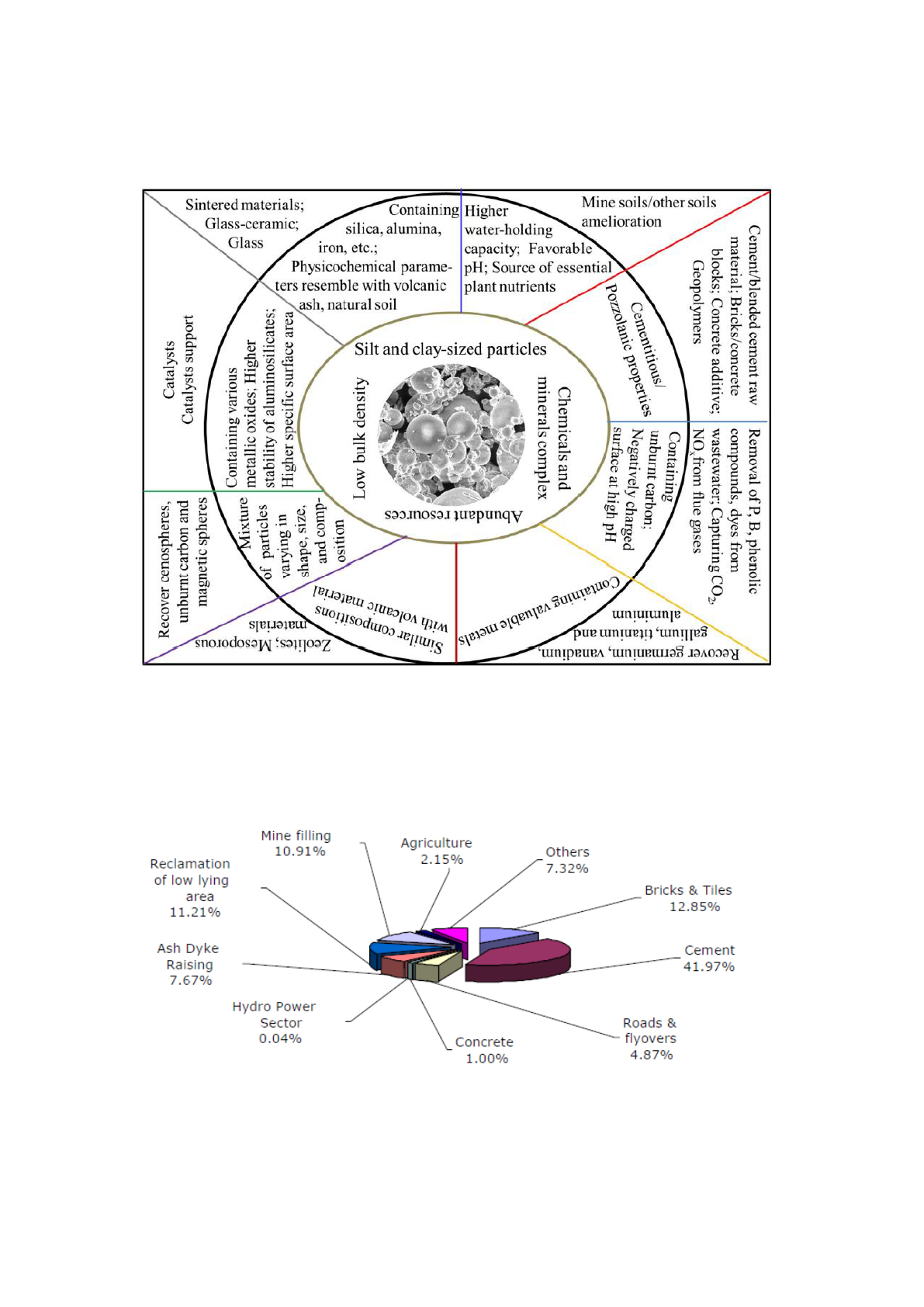

Whatever the exact figure for the utilization of fly ash in India, a significant

proportion of fly ash remains untreated and that there is an urgent need for developing

new recycling methods for it. Current application data for fly ash utilization in India is

illustrated in Figure 12 and described in the following sections.

40 Surabhi

MAJOR TYPES OF UTILISATION

The most important utilization areas of fly ash are as follows :

Cement manufacturing :

The fly ash contains substantial percentage of silica, alumina and lime and can be

used as a partial replacement of Portland cement. The replacement rates normally run

between 20% to 30% but can be higher. Fly ash reacts as a pozzolan with the lime in

cement as it hydrates, creating more of the durable binder. As a result concrete made

with fly ash is stronger and more durable than traditional concrete made with Portland

cement. More over it is less susceptible to chemical attack and hence suitable for

coastal atmosphere [13,14]

Filling of low lying area:

The fly ash especially bottom ash can be suitably utilized for filling low lying areas

over which future construction could be carried out. It can be also used for

reclamation of sea. If reclamation is judiciously implemented a huge quantity of fly

ash can be used for reclamation of land from sea especially in coastal areas like

Paradeep, Puri, Balasore, Astaranga, Gopalpur etc.

Construction of road and embankment:

Fly ash is a lightweight material. Therefore it undergoes lesser settlement and hence

can be used for embankment construction over weak substrate such as alluvial clay or

silt where excessive weight could cause failure. Due to its low compressibility it can

also be used for road construction as a sub grade material [15]

Fly ash brick :

Fly ash can be used for manufacturing of bricks used for building construction. These

bricks are light in weight and stronger than common burnt clay bricks available in our

state. Fly ash can also be used for manufacturing of pavement blocks/tiles normally

used for laying hard, durable and attractive flooring in the courtyards, pavements,

walkways, car parking etc. The use of fly ash for manufacturing of bricks and

pavement tiles will help in preserving land area dug out for clay brick manufacturing,

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 41

prevent soil erosion and reduction in fire wood consumption which cause

deforestation [16]

Ash pond dyke raising:

The ash produced in power plants are disposed off in ash pond in slurry form. Due to

land constraints the dykes of ash pond are raised in stages. The ash from ash pond is

generally used for raising this dyke which in turn saves the borrow material. With

proper drainage arrangement and slope stability the fly ash could be a suitable

material for dyke construction in ash pond[17].

Agriculture:

Since fly ash contains micronutrients like phosphorus, potassium and calcium,

improves water holding capacity and soil aeration, it can be suitably used in

agriculture sector to improve crop yield [18,19,20,21]. Fly ash can also reclaim saline

alkali soil resulting in saving of gypsum.

The govt. needs to frame stringent policies to encourage use of fly ash in road and

embankment construction and reclamation of sea in coastal states of the country. The

govt. should also explore the possibility of use of fly ash in waste water and saline

water treatment.The unburnt carbon recovered from fly ash can be used a

adsorbent[22].

Last but not the least active participation of general public, non government

organization, Research organizations in effective utilization of fly ash is also required

in mitigating the challenge posed by increased fly ash generation in the country in

near future. Several possible uses of fly ash is summarized in following figure 13.

42 Surabhi

Figure 11: Various Possible utilization of fly ash[6]

CEA has shown the report explaining the mode of fly ash utilization in first half of

2015-16.

Figure 12: Mode of Fly Ash Utilisation in first half of 2015-16 [23]

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 43

Fly ash generation & utilization data for the Year 2014-15 (April, 2014 to March,

2015) has been given from 145 (One hundred forty five coal/lignite based thermal

power stations) of various power utilities in the country. A brief summary of status is

given in Table-1below:

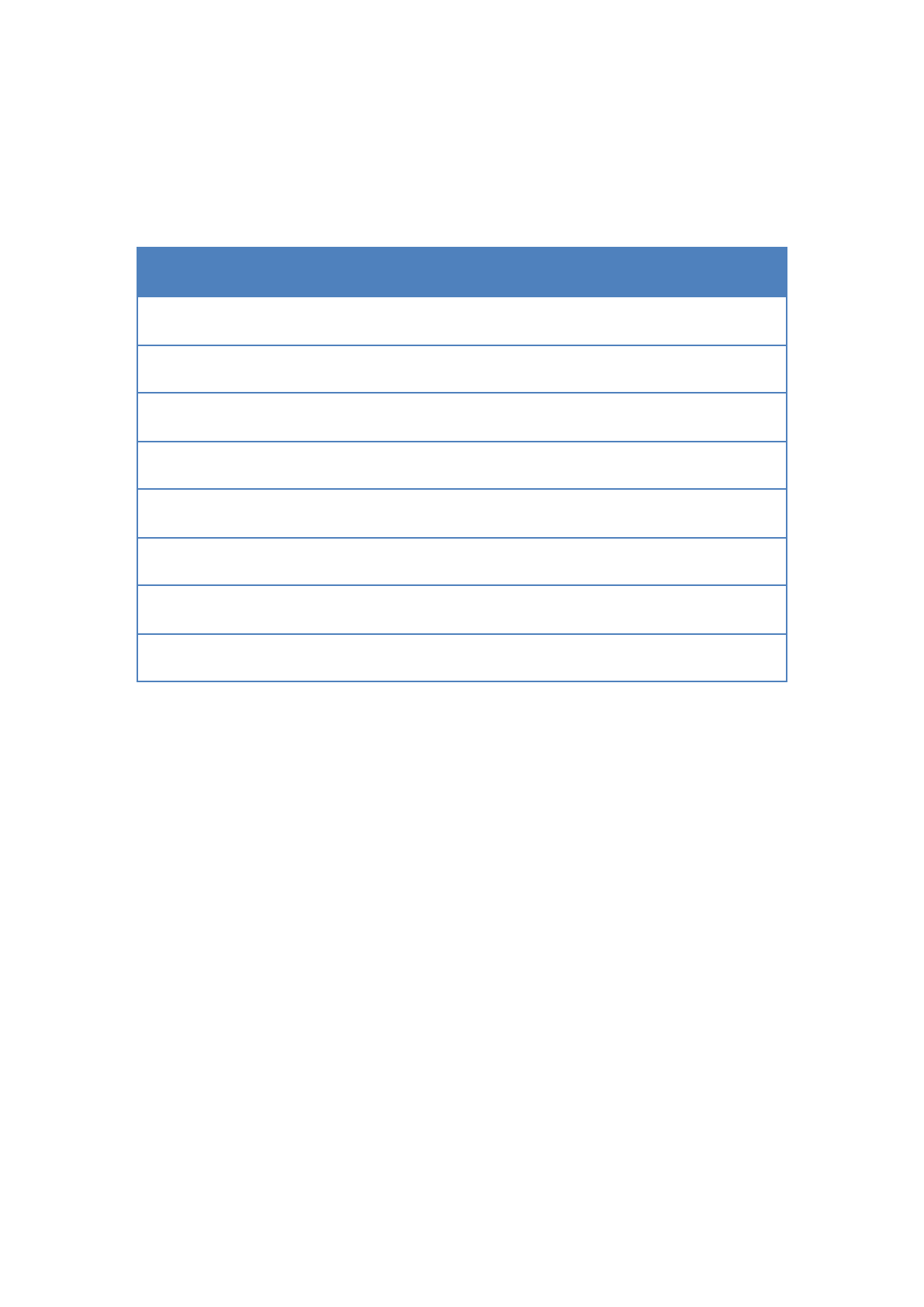

TABLE 1: Summary Of Fly Ash Generation And Utilization During Year 2014-15

Description

1

st

Half year

2014-15

1

st

Half year

2015-16

Number of Thermal Power Stations from which

data was received

146

132

Installed capacity (MW)

1,33,709

1,30,429

Coal consumed (Million tons)

273

257

Fly Ash Generation (Million tons)

92

84

Fly Ash Utilization (Million tons)

49

47

Percentage Utilization

53

56

Percentage Average Ash Content (%)

33.65

33.23

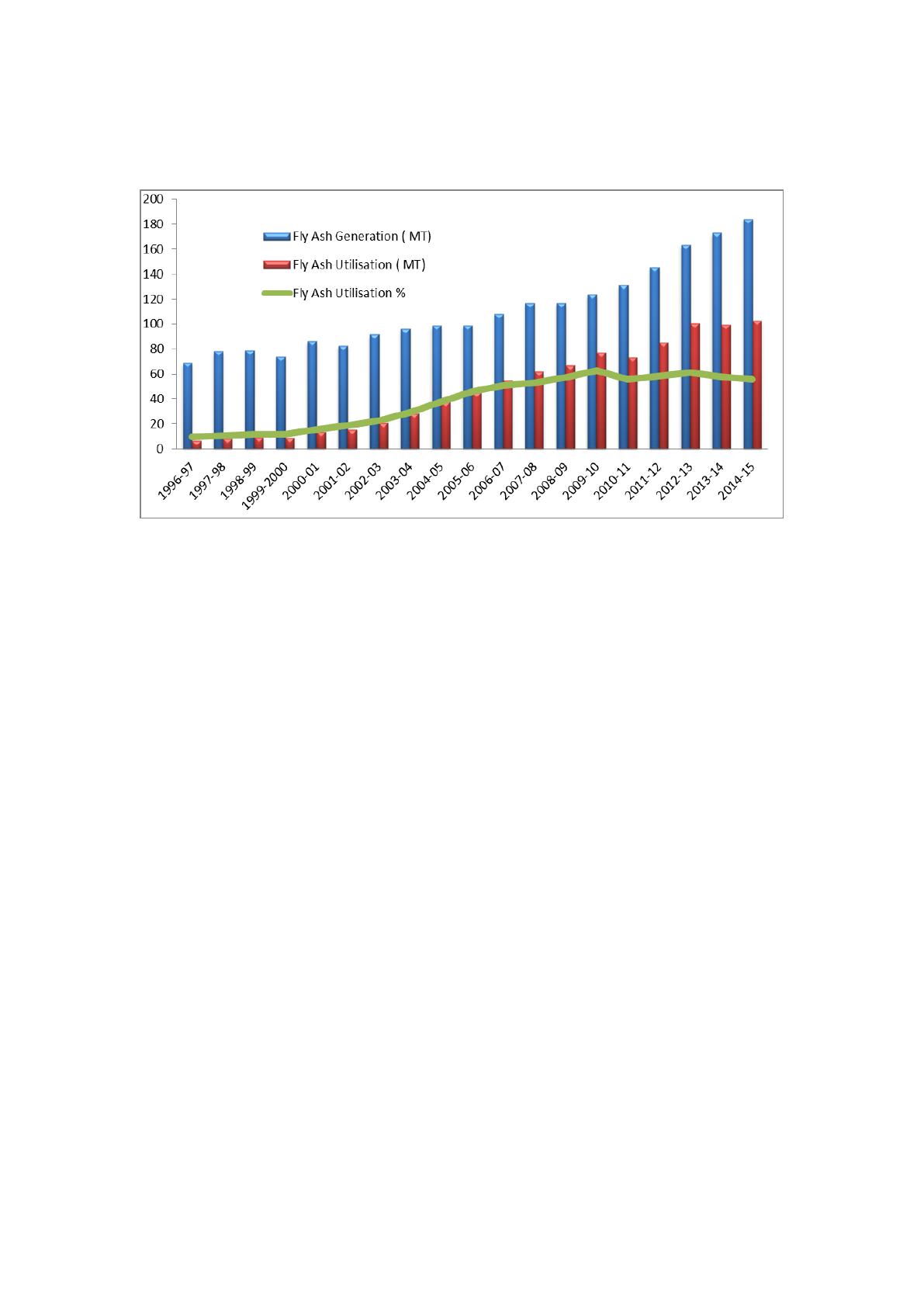

Central Electricity Authority has been monitoring since 1996-1997the fly ash

generation and its utilization at coal/lignite based thermal power stations in the

country. Based on data of fly ash generation and utilization received from Thermal

Power Stations/Power Utilities since 1996-97, the progressive fly ash generation and

its utilization for the period from 1996-97 to 2014-15 is given in figure below.

44 Surabhi

Figure 13: Fly Ash Generation and Utilization During The Period From 1996-97 To

2014-15

CHEMICAL CHARACTERISTICS OF INDIAN FLY ASH

The Indian low-lime fly ashes are characterized by relatively higher concentration of

SiO

2

and Al

2

O

3

and lower contents of Fe

2

O

3

. This implies higher fusion temperature

for these fly ashes and, consequently, the chances of lower glass formation, if the ash

is not subjected to relatively high temperature[24].

While in the low-calcium fly ashes the silica content is almost double of the alumina

content, in the high-calcium fly ashes the content of these two oxides is by and large

comparable or close to each other. The iron oxide context in the high-lime fly ash is

significantly higher than in the low-lime variety.

Studies involving sieving, sink-float [25] and magnetic separation, carried out to

study the heterogeneity of fly ashes, revealed that the variability of composition is

more in the high-lime fly ashes[26]. The unburnt carbon present in fly ash can be

recovcered by froth flotation or oil separation method [27].

A study has been conducted to classify the oxide compositions of fly ashes using

radial basis function neural network [28].

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 45

COMPOSITION OF FLY ASH

It is widely known that the reactivity of fly ashes is dependent on their glass content

and other mineral phases present. It has been observed that the Indian fly ashes are

more crystalline than those obtained in other countries, the glass content ranging from

47.0 to 60.9 percent [29]. The network theory of glass formation [30] provides a

theoretical basis to explain the relatively poorer glass content in the Indian fly ashes.

Since the ratio of network formers (SiO

2

+ Al

2

O

3

+ Fe

2

O

3

) to network modifiers

(Na

2

O + K

2

O + CaO + MgO) in the Indian fly ashes is very high and imbalanced, the

glass content is low.

Depending upon the source and makeup of the coal being burnt, the composition of

fly ash and bottom ash vary considerably. Fly ash includes substantial amounts of

silicon dioxide and calcium oxide which are the main ingredients of many coal

bearing rocks[31] . Coal Bituminous coals, sub-bituminous and lignite coals from

different mines are substantially different from each other in the combustion process

[32].

Coal blending is now used for operational and financial benefits. This results in a

wide range of boiler and precipitator operating conditions. Precipitating fly ash from

difficult coals can be improved with conditioning systems. However, the furnace and

its associated equipment can still cause problems in the precipitator, particularly coal

mills, burners, and air pre heaters. The operation of coal burners, together with the

setting of the coal mills and their classifiers, affects the percentage of unburned

carbon(UBC) in the fly ash. The use of Low NOx burners increases this percentage,

and causes re-entrainment and increased sparking in the precipitator. Further, the UBC

tends to absorb SO

3

, which in turn increases the fly ash resistivity[33]

Contaminated constituents of fly ash depend upon the specific coal, but may include

one or more of the following elements in quantities or trace amounts to varying

percentages: Arsenic, molybdenum, selenium, cadmium, boron, chromium, lead,

mangnesium.

46 Surabhi

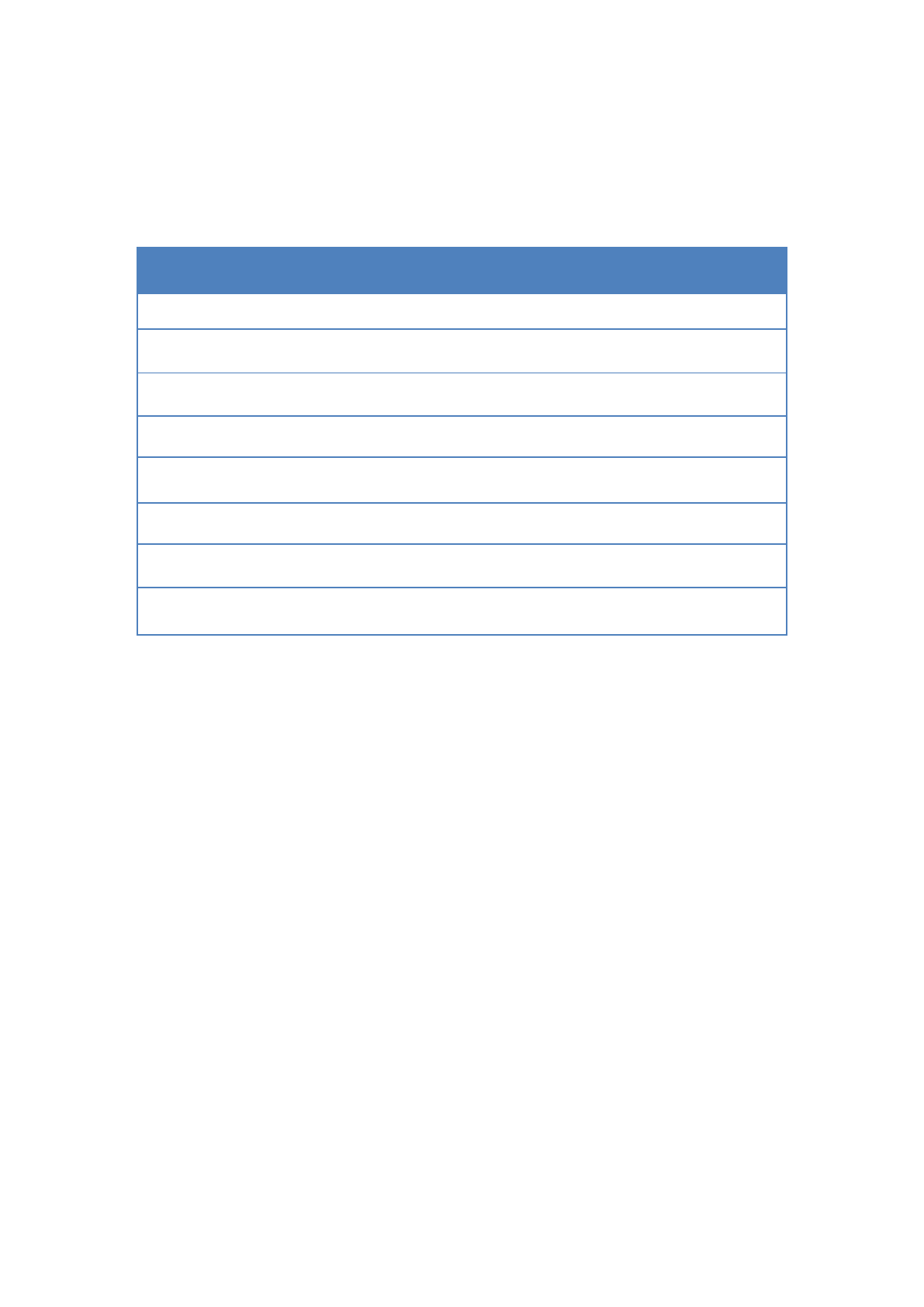

Table 2: Normal Range Of Chemical Composition For Fly Ash Produced From

Different Coal Types (Expressed As Percent By Weight).

Component

Bituminous

Sub bituminous

Lignite

Silicon dioxide,SiO2

20-60

40-60

15-45

Aluminium oxide,Al2O3

5-35

20-30

10-25

Iron oxide,Fe2O3

10-40

4-10

4-15

Calcium oxide,CaO

1-12

5-30

15-40

Magnesium oxide,MgO

0-5

1-6

3-10

Sulphur Trioxide,SO3

0-4

0-2

0-10

Sodium Carbonate,Na2O

0-4

0-2

0-6

Potassium oxide,K2O

0-3

0-4

0-4

It is known that the fly ash is separated from the gases generally with the help of

multi-field electrostatic separators and the specific surface areas of the flyashes

collected typically vary from about 250m

2

/kg to 850 m

2

/kg. Since the final collection

hopper contains materials of all the fields, the specific surface areas of the mixed fly

ashes as received at the user end are on the coarser side and quite variable [34].

For applications in cement and concrete one of the important quality tests is to check

their lime reactivity potential under standard test conditions [35].

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 47

Table 3: Specification of the Indian Low-lime FlyAsh vis-à-vis US/European

Standards

Parameters

ASTM C-618

EN 450

IS 3812

SiO2 per cent, min

---

---

35

Reactive SiO2, per cent, min

---

25

20

SiO2 + Al2O3 + Fe2O3, per cent, min

70

---

70

Total/reactive CaO per cent, max

---

10

10

Residue on 45 μm per cent, max

34

40

34

Blaine’s SSA, min, m2 / kg

---

---

320

Lime reactivity, N/mm2, min

---

---

4.5

Cement Reactivity, per cent, min

75

75

80

GOVERNMENT OF INDIA INITIATIVES ON FLY ASH

According to The Gazette of India dated JANUARY 27, 2016 , Ministry Of

Environment, Forests And Climate Change Notification, New Delhi, the 25

th

January, 2016. The coal or lignite based thermal power plants shall comply with the

above provision in addition to 100% utilization of fly ash generated by them before

31

st

December, 2017.

The coal or lignite based thermal power plants shall within a radius of three hundred

kilometers bear the entire cost of transportation of ash to the site of road construction

projects under Pradhan Mantri Gramin Sadak Yojna and asset creation programmes of

the Government involving construction of buildings, road, dams and embankments.

Ministry of Environment, Forests and Climate Change (MoEFCC) has revised norms

for fly ash usage and disposal by granting permission to use it for agriculture. The

ministry has also made it mandatory for power plants to give fly ash free of cost to

users within 300-kilometre-radius.

48 Surabhi

According to MoEFCC, the fly ash utilisation in the country was 57.63 per cent in

2014 as against 13.51 per cent in 1999. About 20,000 hectares of land resources can

be saved annually by effectively utilisation of fly ash in India.

CONCLUSION

The generation of coal fly ash is anticipated to increase for many more years, as a

result of the world's increasing reliance on coal-fired power generation.

Understanding the generation and characterizations provides a background and a basis

for the alternative uses of fly ash. This review has attempted to investigate the

production of fly ash at the global level and covers a wide range of applications to

understand the status of fly ash utilization.

The knowledge of the various ways to use fly ash, such as in the construction industry,

Agriculture,waste water treatment , is essential for better management of fly ash and

the reduction of environmental pollution. However, there are still some limitations for

current applications. The long-term effect of fly ash addition on field scale crop

productivity and soil properties needs to be investigated. Fly ash reutilization is

significant in the construction industry; however, some physical and engineering

properties are also required to meet the standards. To promote the usage of fly ash,

state and local governments should issue preferential policies that encourage its

recycling, such as the preferential purchase of recycled fly ash products and reduction

of the overall effective tax.

This may be summarized as;

1. Utilization of fly ash is 56.04% in the first half of 2015-2016, which is very

much behind the required target.

2. Areas having large prospective of fly ash utilization needs to be discovered for

inceasing the overall utilization of fly ash in India.

3. Technological advancement is required for collection, storage and disposal

facilities of fly ash so that fly ash in dry form could be made available to its

users.

4. The states and districs where TPPs are located needs to promote fly ash

utilization; construction of building/highways/roads/flyovers and other

infrastructure projects.

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 49

5. The use of fly ash in the projects within a radius of 300km of any TPP as

mandated in MoEF and CC’s notification of 25th Jan,2016 has to be ensured

right from project formulation stage.

6. Utilization of fly ash in agriculture is below expectation because of presence

of heavy metal and radioactive elements in fly ash. Theses apprehensions are

mandatory to be addressed for increasing fly ash utilization.

7. There is need to encourage industry-institute interaction for enterpreneur

development,creating awareness and organizing training workshops.

REFERENCES

[1] World Oil Outlook , OPEC Secretariat background paper, 15th International

Energy Forum Ministerial , Algiers, Algeria, 26th – 28th September, 2016

[2] Mehta, 1993- international conference on the area of fly ash, silica fumes,

slag & other mineral by products, ACI SP-79, American concrete Institute,

Detroite, pp. 1-48

[3] http://www.credenceresearch.com/report/fly-ash-market

[4] ASTM C618, Annual bool of ASTM standard volume 4.02, ASTM

International

[5] Nath, P. Sarkar, P., 2011, Effect of fly ash on durability properties of high

strength of high strength concrete, Procedia E ng. 14, 1149-1156

[6] Tensing,2011, “Grenner Building material with fly ash”, Asian journal of

civil engineering(Building and Housing)., Vol 12, No. 1, pp 87-105

[7] Clarke L B. Utilization Options for Coal Use Residues: An International

Overview. Proceedings of the Tenth International Ash Use Symposium,

ACAA, Orlando, Florida, EPRI Report No. TR-101774, January (1993), 2,

66-1 to 66-14

[8] Manz O E, Faber J H, Takagi H. Worldwide Production of Fly Ash and

Utilization in Concrete. Proceedings of the Third International Conference on

the Use of Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete,

Supplementary Papers, Compiled by Mohamad Alasali, Trondheim, Norway,

(1989), 1-15.

[9] Manz O E. Worldwide Production of Coal Ash and Utilization in Concrete

and Other Products. Proceedings of the Tenth International Ash Use

Symposium, ACAA, Orlando, Florida, January (1993), 2, 64-1 to 64-12.

50 Surabhi

[10] Lin, B., Cerato, A.B., Madden, A.S., & Elwood Madden, M.E. (2013). Effect

of Fly Ash on the Behavior of Expansive Soils: Microscopic Analysis.

Environmental & Engineering Geoscience, 19(1), 85–94.

[11] Z.T. Yao et al.,2015, “ A comprehensive review on the application of coal fly

ash”, Earth-Science Reviews 141, 105–121

[12] www.tifac.org.in, Fly ash Mission, Technology Information Forecasting &

Assessment Council (TIFAC), Department of Science & Technology,

Ministry of Science & Technology, Government of India, Technology

Bhawan, New Delhi

[13] Dhadse, P. Kumari, L.J. Bhagia, 2008“ Fly ash characterization, utilization &

Government intiatives in India- a review, J Sci Ind Res. 67, pp 11-18

[14] U. Bhattarcharjee, T. C. Kandpal,2002, “ Potential of fly ash utilization in

India, Energy, 27, pp. 151-166

[15] Lentinen P,2001, Fly ash mixtures as flexible structural material for low

volume roads, Finnra reports 70/2001

[16] Surabhi, Udayabhanu G., Nikkam Suresh, “Removal of unburnt carbon from

fly ash to use it as an adsorbent”,Pollution Research 34 (4),2015, 687-692

[17] Sinha S N & Agarwal MK,1999, “ Fly ash; A new resource material cited in

fly ash disposal and deposition; Beyond 2000 AD, edited by U Dayal et al

( Narosa Publishing House, New Delhi) 70-75

[18] A. C. Chang, L.J.Lund, A.L. Page, et.al., 1977,“ Physical properties of Fly

ash amended soils, J Environ Qual, 6, pp. 267-270

[19] Ram, L.C., Srivastava, N.K., jha, S.K., Sinha, A.K., Masl,R.E., Selvi,

V.A.,2007b, “ Management of Lignite Fly ash for improving soil fertility &

crop productivity”, Environ. Management, 10,438-452

[20] Ram, L.C., Srivastava, N.K., Tripathi, R. C., Thakur, S.K., Sinha, A.K., Jha,

S.K. Masto, R.E., Mitra, S.,2007 a, “ Leaching behavior of lignite Fly ash

with column tests, Environ. Geol. 51, 1119-1132

[21] Pandey, V. C., Singh, N., 2010, Impact of fly ash incorporation in soil

system”, Agaric. Ecosyst. Environ. 136, 16-27

[22] Surabhi, Anil Kumar Chaudhary, “A study on the utilization of fly ash in

concrete”, ESAIJ, 10(2), 2015,41-45

[23] The Gazette of India dated JANUARY 27, 2016 , MINISTRY OF

ENVIRONMENT, FORESTS AND CLIMATE CHANGE NOTIFICATION,

New Delhi, the 25th January, 2016

Fly ash in India: Generation vis-à-vis Utilization and Global perspective 51

[24] Chatterjee K. Anjan, 2010, Second International Conference on sustainable

construction material & Technologies, June 28- June 30, Coventry University

and the University of Wisconsin Milwankee, centre for By- products

Utilization, ISBN 978-1-4507-1490-7

[25] Surabhi, Udayabhanu G., Nikkam Suresh, “Recovery of Carbonaceous

materials from Bokaro Thermal Power Plant Fly Ash by Froth Floatation”,

Proceedings of the International Seminar on Mineral Processing Technology,

2005,The McGraw-Hills Companies,pp.333-340

[26] Das, S.K. and Yudhbir (2003), “Chemistry and Mineralogy of Some Indian

Fly Ashes”, The Indian Concrete Journal, September, 1491 – 1494.

[27] Surabhi, Udayabhanu G., Nikkam Suresh, “Methodologies for Recovery of

Carbonaceous Material from Coal Combustion Byproducts –Powder

Processing and Technology, Trans-Tech Publication (Germany), 2004,pp.1-8.

[28] Nataraj, M.C., Jayaram, M.A. and Ravikumar, C.N.(2006),“Group-indexing

Fly Ashes through Radial Basis Function Network”, The Indian Concrete

Journal, July, 39 – 45.

[29] Fournier, B., Lu, D., Charland, J.P, and Li, J. (2004), “Evaluation of Indian

Fly Ashes for Use in HVFA Concrete, Part 1: Characterization”, The Indian

Concrete Journal, November, 22-30.

[30] Zacchariassen, W.J. (1932), “The Atomic Arrangement in Glass”, J. Am.

Ceram. Soc., 54, 3841 – 3951

[31] Surabhi, Udayabhanu G., Nikkam Suresh, “Characterization of Unburnt

Carbon Recovered from Fly Ash by Froth Flotation”, Proceedings of the

international seminar on Mineral Processing Technology, 2006, Chennai,

India, pp. 128-133.

[32] Md. Ghazali, Prof. O.P. Kaushal, 2015,” Characteristics of fly ash from

thermal power plants and its management along with settling pond design”,

vol-1,issue-4, 24-32

[33] Surabhi, Udayabhanu G., Nikkam Suresh, “Characterization and

Beneficiation of carbonaceous material in Indian fly ash”, Journal of Indian

Chemical Society, vol.91, 2014 January,73-80

[34] Chatterjee, A.K. (2008), “Enhancing the Potential of Industrial use of the

Indian Fly Ashes Through Mechano-Chemical Activation – Prospects and

Problems”, International Conference on Mechano-Chemistry and Mechanical

Alloys, National Metallurgical Laboratory, Jamshedpur, India.

52 Surabhi

[35] Mullick, A.K. (2005), “Use of Fly Ash in Structural Concrete : Part 1 –

Why ?”, The Indian Concrete Journal, May, 13–22.