Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 911

!

J. Mater. Environ. Sci., 2020, Volume 11, Issue 6, Page 911-921

http://www.jmaterenvironsci.com!

Journal(of(Materials(and((

Environmental(Science(

ISSN(:(202 8 ;2508(

CODEN(:(JMESCN(

Copyright(©(2020,(

University(of(Mohammed(Premier((((((

(Oujda(Morocco(

Fly Ash: Production and Utilization in India - An Overview

Aadil Yousuf

1

,

Shahzada Omer Manzoor

1

, Mudasir Youssouf

2

,

Zubair A. Malik

3, *

and Khawar Sajjad Khawaja

4

1

Department of Civil Engineering, National Institute of Technology, Srinagar J&K, (India) 190006.

2

Department of Environmental Sciences, Govt. HSS Chittergul Anantnag J&K, (India) 192201.

3

Department of Botany, Govt. HSS Hardutooru Anantnag J&K, (India)192201.

4

DeLeuw Cather International Limited, UAE.

!

1.( Introduction

Electricity is the backbone of modern world and particularly the machinery which acts as a driving

force for economies globally has direct or indirect dependence on electricity. Since 1920, coal is being

used as a basic fuel for power generation and billions of tons of fly ash and other by-products have been

created till now and the improper disposal of these by-products has had a considerable negative influence

on the environment. Fly ash, if not managed properly pollutes water, air and soil, however the recent

advancements in engineering have made it a useful resource in many areas especially in construction

industry. When pulverised coal is placed in combustion chamber of boiler it immediately ignites

producing mineral residue which is in molten state. After extracting heat from the boiler, the molten

residue cools, hardens and ash is formed. The coarser part of this residue referred to as bottom ash falls

to the bottom of combustion chamber while as the finer ash particles remain suspended within the flue

gas and these finer particles are removed by particulate emission control devices like electrostatic

precipitors (ESPs). India is the third-largest generator of coal-based power after China and the United

Abstract

Fly Ash is the fine particulate residual outcome of pulverized coal burning

obtained primarily from the coal-based electricity generation plants. Considering

the exponential increase in population around the world, the electrical energy

demand as of now is at an all-time high and coal-based power plants are

responsible for satisfying major part of this demand especially in developing

countries. Owing to this extra load on coal-based plants, there is a significant

increase in the production of fly ash from these plants and the disposal of fly ash

which is considered a deleterious product for environment is becoming a concern

for everyone. In this paper, a brief review about the composition, production and

utilization has been provided with special reference to India. Also, several options

have been provided regarding the effective usage of fly ash in fields like the

Construction industry, Agriculture sector and Geotechnical field of engineering.

Received 16 April 2020,

Revised 22 May 2020,

Accepted 23 May 2020

Keywords

! Fly Ash,

! Soil Stabilization,

! Environment,

! Geotechnical

Engineering

!

malikmzubair[email protected];

Tel: +91 7889687063

!

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 912

!

States [1]. The Indian coal is low grade and has high ash content (30-45%) as compared to imported

coals (10-15%), so large quantities of fly ash are generated, 217.04 Million tons in 2018-19 [2]. The

generated fly ash requires large areas for disposal as well as remains a source of environmental pollution

[3]. In India an area of 65000 acres of land is being occupied by ash ponds and is its generation is

expected to cross 225 million tones by the year 2020 [4]. FA disposal in an unscientific way affects the

local ecosystems due to the heavy metal pollution through erosion and leachate generation. Apart from

occupying large areas, fly ash, if not managed well, by virtue of its weightlessness can become airborne.

Dumped FA contaminates surface and groundwater, soils and vegetation by mobilization of its

hazardous metals [5]. So, there are two major constraints of coal-based thermal power plants, (1) land

requirement for fly ash disposal, and (2) controlling the pollution, suspended particulate matter (SPM)

as well as the movement of heavy metals into groundwater and food chain [6]. In order to reduce the

impact of fly ash on the environment and to lower the the requirement of land for its disposal, various

notifications have been issued by Ministry of Environment and Forest to achieve 100% utilization of fly

ash [7]. Since 1994, under the Ministry of Science and Technology (GOI), different technologies have

been adapted for safe and productive utilization of fly ash and this increased the utilization of fly ash

from 6.64 million tons in 1996-97 to 168.40 Million tons in 2018-19 [8]. For various reasons including,

prevention of environmental pollution, reduction in disposal cost as well as dumping area, replacement

of other costly resources and to gain financial returns, fly ash has been used in the form of an alternative

to another industrial resource, process, or application [9]. Coal fly ash can be used in the construction

industry, structural fill and pavement utilization, soil reclamation, soil ameliorant, an additive in

anaerobic digestion and composting, zeolite synthesis, metal recovery, low-cost adsorbent for various

gaseous and aqueous applications [10].

2.( Fly Ash Properties

Physically, fly ash occurs as very fine particles having minute average diameter, and has low to

medium bulk density, high surface area and light texture. Chemically, Fly Ash is considered as

amorphous and mixture of Ferro-alluminosilicate minerals. However, the chemical and physical

properties of fly ash depend on the type of coal used, combustion methodology adopted, and temperature

regulation during combustion and method of collection. Following are some of the physical and

chemical properties of fly ash:

•! Even though there is some degree of variability of constituents owing to the variation in coal

source, however, more often the primary constituents are SiO

2

, CaO, Al

2

O

3

, Fe

2

O

3

along with

some amounts of MgO, Na

2

O, etc.

•! Fly ash particles generally fall in silt range and are typically finer as compared to lime and Portland

cement. The size of fly ash particles varies from 10 to 100 microns having a spherical shape.

•! Colour of fly ash principally depends on the mineral composition of coal source, it may have a

dark or black shade or tan colour.

•! The specific gravity of fly ash depends on the degree of coal pulverization, particle shape, and

coal type. It varies considerably from 1.6 to 3.1 [11].

•! Fly ashes sourced from bituminous coals tend to be acidic and those from sub-bituminous tend to

be alkaline, this is heavily dependent on the chemical composition of ash [12,13].

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 913

!

•! Even though fly ash has greater surface area but the Cation Exchange Capacity (CEC) is on the

lower side due to the non-plastic nature, however, CEC can be increased by modifying the fly ash.

Also, lower CEC signifies lesser water absorption and this property can be and has been used

favourably while stabilizing expansive soils.

3.( Fly Ash Classification:

•! Class C Fly Ash has high cementing abilities and these are formed from the burning of sub-

bituminous coal. This kind of fly ash has lime in excess of 20% and also does not need an

activator (based on ASTM C 618 standards) for the formation of cementitious compounds

•! Class F Fly Ashes are generated from the combustion of bituminous and anthracite coals. These

ashes have less than 10% lime content and need an activator (based on ASTM C 618 standards)

like Portland cement, quick lime, etc. for the formation of cementitious compounds.

4.( Fly Ash Production and Utilization in India:

As of now, in India 72% of the total electricity is produced by the coal-based electricity generation

plants and this production rate and dependence on such plants is expected to remain the same in the

coming years. The fly ash generation during 2018-19 is 217.04 million tonnes due to combustion of

667.43 million tonne Coal/Lignite and fly ash utilization is around 168.40 million tonne which suggests

an effective usage of 77.59% respectively [8]. Presently, fly ash is used in the construction industry on

a large scale like in the manufacturing of Portland pozzolana cement, construction of roads, dams,

stabilization of slopes, etc. The following are some of the official figures (Table 1) published by the

Central Electricity Authority in the annual report of 2018-19 [8].

Table 1: Fly ash generation and utilization during the year 2014 to 2019*

Description

2014-15

2015-16

2016-17

2017-18

2018-19

Number of Thermal Power

Stations

145

151

155

167

195

Installed Capacity (MW)

138915.80

145044.80

145044.80

177070.00

197966.50

Coal Consumed (Million Tons)

549.72

536.64

536.4

624.88

667.43

Average Ash Content (%)

33.50

32.94

33.22

31.44

32.52

Fly Ash Generation

(Million Tons)

184.14

176.74

169.25

196.44

217.04

Fly Ash Utilization (Million

Tons)

102.54

107.77

107.10

131.87

168.40

% Utilization

55.69

60.97

63.28

67.13

77.59

*Source: CEA (Central Electricity Authority) 2014 to 2019.

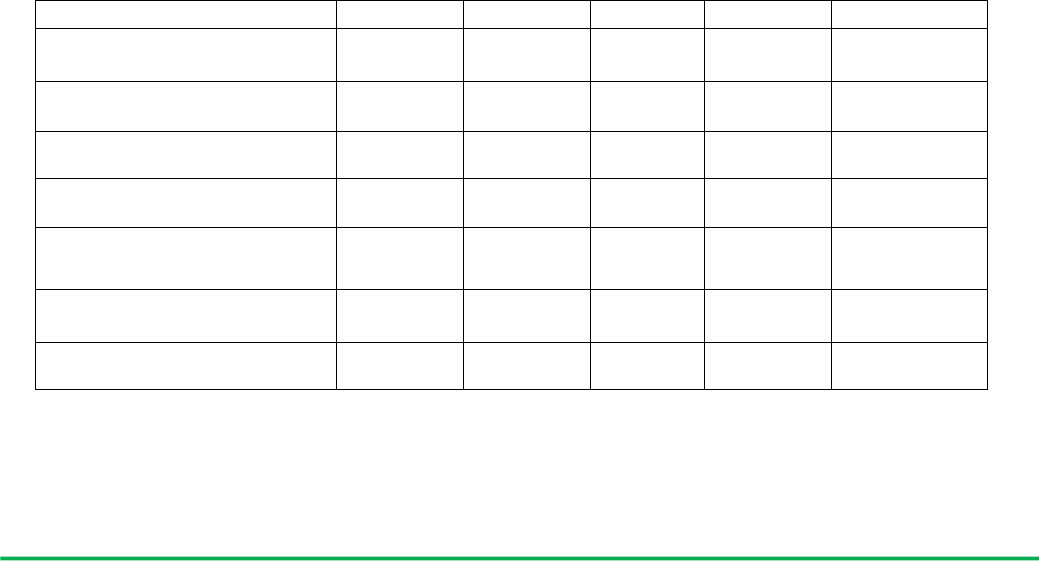

There are a number of areas where fly ash has been used in all these years and some figures outlining

the actual sector-wise usage have been mentioned below (Table 2 and Figure 1).

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 914

!

Table 2: Fly ash utilization during the year 2018-19*

S.NO.

Mode of utilization

Utilization (Million tons)

% Utilization

1

Cement.

58.3401

26.88

2

Mine Filling

10.1002

4.65

3

Bricks and Tiles.

21.6097

9.96

4

Reclamation of Low Lying Area.

29.3177

13.51

5

Ash Dyke Raising

21.5734

9.94

6

Roads and Fly Over

9.7244

4.48

7

Agriculture.

1.3769

0.63

8

Concrete

1.7742

0.82

9

Hydro Power Sector

0.0000

0.00

10

Others.

14.5809

6.72

11

Unutilized Fly Ash

48.6405

22.41

Total

217.0380

100.00

*Source: CEA annual report 2018-2019.

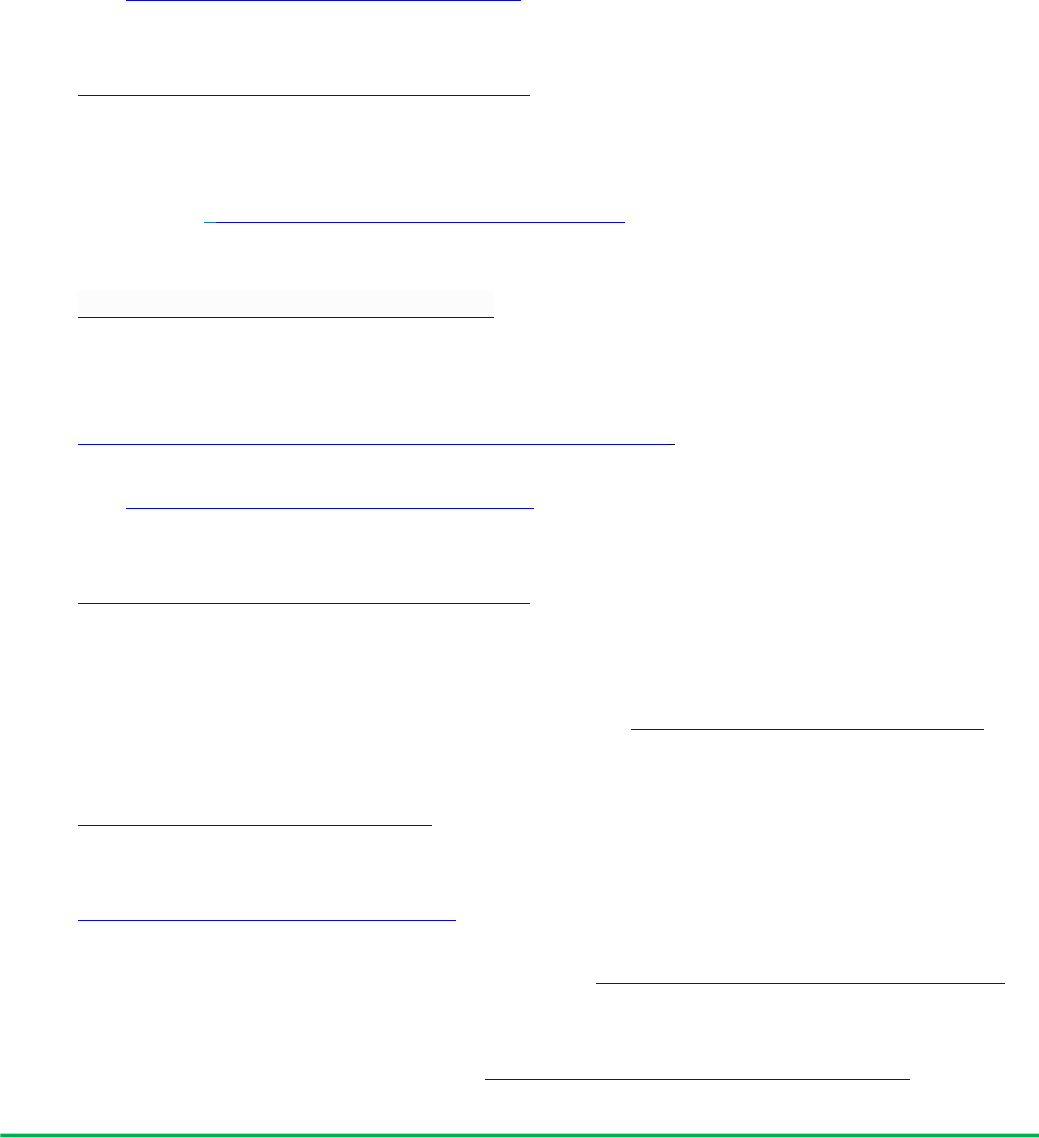

Figure 1: Major modes of fly ash utilization during the year 2018-19

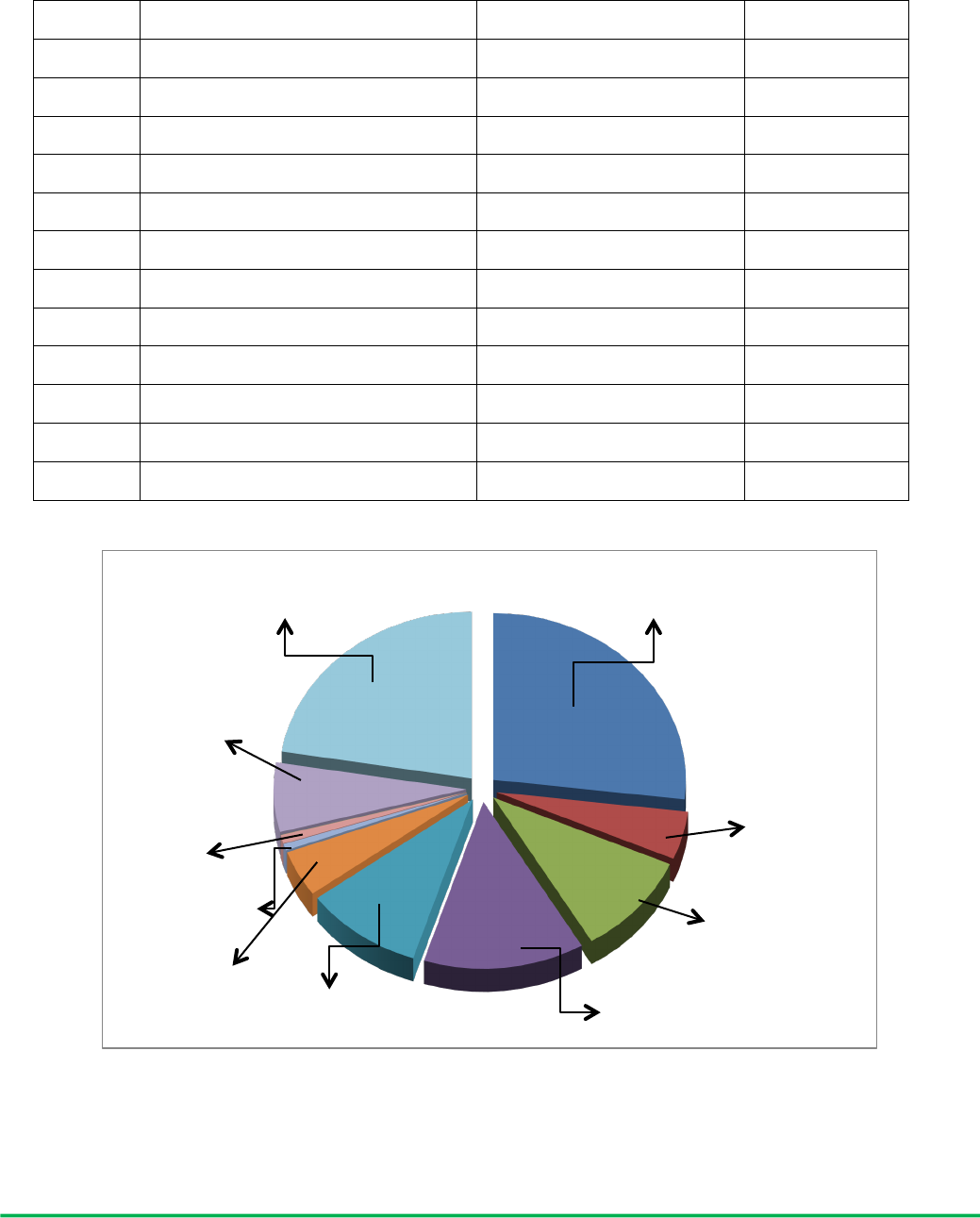

Fly ash generation and utilization during the period 1996-97 to 2018-19 are given below (Table 3 and

Figure 2).

Cement

26.88%

Mine filling

4.65%

Bricks and Tiles

9.96%

Reclamation of low

lying areas

13.51%

Ash Dyke Raising

9.94%

Roads and Flyovers

4.48%

Agriculture

0.63%

Concrete

0.82%

Hydro Power Sector

0.00%

Others

6.72%

Unutilized Fly Ash

22.41%

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 915

!

Table 3: Fly ash generation and utilization during the period 1996-97 to 2018-19

S. NO.

Year.

Fly ash generation

(Million ton).

Fly ash utilization

(Million ton).

% Utilization

1

1996-97

68.88

6.64

9.63

2

1997-98

78.06

8.43

10.80

3

1998-99

78.99

9.23

11.68

4

1999-00

74.03

8.91

12.03

5

2000-01

86.29

13.54

15.70

6

2001-02

82.81

15.57

18.80

7

2002-03

91.65

20.79

22.68

8

2003-04

96.28

28.29

29.39

9

2004-05

98.57

37.49

38.04

10

2005-06

98.97

45.22

45.69

11

2006-07

108.15

55.01

50.86

12

2007-08

116.94

61.98

53.00

13

2008-09

116.69

66.64

57.11

14

2009-10

123.54

73.33

62.60

15

2010-11

131.09

73.13

55.79

16

2011-12

145.41

85.05

58.48

17

2012-13

163.56

100.37

61.37

18

2013-14

172.87

99.62

57.63

19

2014-15

184.14

102.64

55.69

20

2015-16

176.74

107.77

60.97

21

2016-17

169.25

107.10

63.28

22

2017-18

196.44

131.87

67.13

23

2018-19

217.04

168.40

77.59

*Source: Central Electricity Authority.

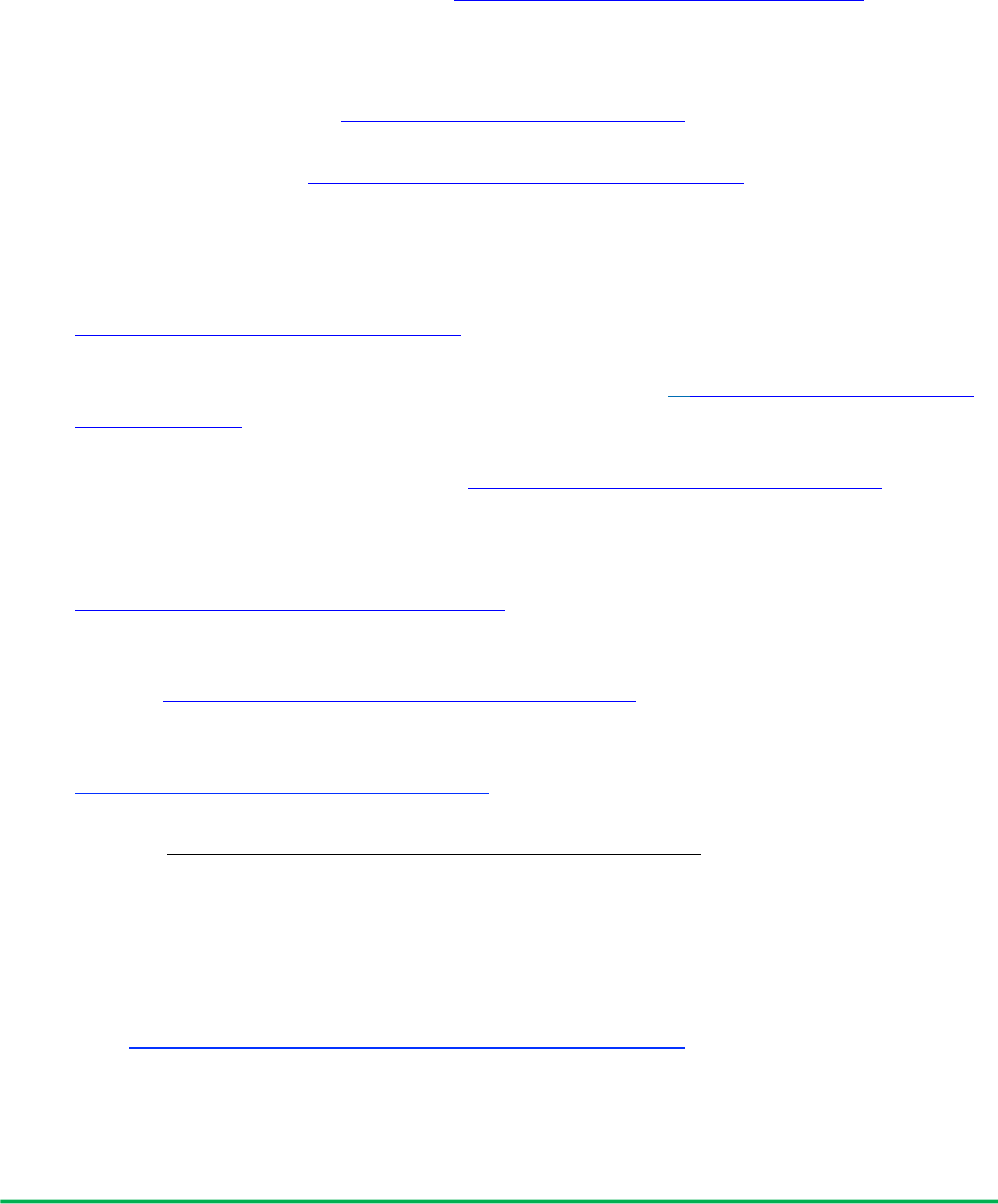

Figure 2: Fly ash generation and utilization (percentage) from 1996-2019

0

50

100

150

200

250

Fly!Ash!generation!(Million! Ton) Fly!Ash!utilization!(Million! Ton) %! Utilization

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 916

!

5.( Utilization of Fly Ash in diverse fields:

5.1 Utilization of Fly Ash in Construction Industry:

5.1.1: Usage of Fly Ash in Portland Cement Concrete: Fly Ash is used as an admixture to improve upon

the performance of concrete and lowering the cracking potential [14]. The lime percentage in Portland

cement is often more than 60 percent and some part of this lime exists as free lime during the process of

hydration which in turn reacts chemically with silicates of fly ash resulting in the formation of

cementitious compounds. In India utilization of fly ash by cement industry amounts to around 60.11

million-ton of the total production in the 2018-19 calendar year [8]. Using fly ash in Portland cement

we get to see a considerable decrease in bleeding, shrinkage, heat of hydration and an increase in

workability, durability and ultimate strength apart from the monetary savings.

5.1.2. Usage of Fly Ash in Building Materials like Bricks: There are two positive aspects of using fly

ash for manufacturing bricks, tiles, etc. One is the effective utilization of fly ash whose disposal

otherwise becomes a problem and second is the preservation of topsoil which can be used for agricultural

purposes instead of brick-making. The fly ash based bricks are known to have higher compressive

strength and are lightweight. According to the official figures of Central Electricity Authority 0.70

million-ton of fly ash was used for brick/tile/block making in 1998-99 while as in 2018-19 it has

increased to 21.61 million ton constituting 9.96 % of the total fly ash generation [8].

5.1.3. Fly Ash in stabilized base course: Fly Ash is greatly useful in road construction. A stabilized base

course can be produced by mixing together fly ash, lime or Portland cement, and aggregates in definite

proportions. Usually, 12 to 14 percent fly ash is mixed with 3 to 5 percent of lime. The resulting mixture

when placed looks like cement stabilized base. This kind of road base is also called as pozzolanic-

stabilized mixtures. These road bases are strong, more durable, and less costly as compared to other base

materials. Also, these can be placed using conventional equipment. However, care has to be taken

regarding the seasonal variations and these require proper sealing and protection with asphalt.

5.1.4. Fly Ash in Pavements: In asphalt pavements fly ash can be used as filler which in turn will increase

rutting resistance, stiffness of mortar mix and overall durability of asphalt mix. Apart from being an

economical alternative, it will also help in reducing the stripping potential of asphalt pavement. Fly ash

mixed properly with water and other minerals can be used to fill voids under pavements or help in

supporting concreting pavements at specific grades by suitably drilling and injecting ground under

pavements.

5.2 Application of fly ash in agriculture:

Soil properties, as influenced by fly-ash application, have been studied by several workers for using it

as an agronomic amendment. Physical and chemical properties of soil due to fly-ash amendment vary

according to the original properties of soil and fly ash and therefore, the mode of use in agriculture is

different and depends on the characteristics of soil or soil type [15, 16] According to the CEA 2018-19

report, agriculture use of fly ash is 1.38 billion tons’ sums up to 0.63% of total fly ash generation [8].

5.2.1. Soil texture: The fly ash addition to soil changes its soil texture due to the textural manipulation.

Several experiments have been performed to measure the physical properties for a variety of soils mixed

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 917

!

with up to 50% fly-ash, which revealed that soil fly-ash mixture tends to have lower bulk density, higher

water-holding capacity and lower hydraulic conductivity than soil alone [3]. Application of high rates

of fly-ash can change the surface texture of soils, by increasing the silt content [17]. Fly-ash addition at

70 tons per hectare has been reported to alter the texture of sandy and clayey soil to loamy [10]. Addition

of fly-ash at 200 tons per acre improved the physical and chemical properties of soil and shifted the

USDA textural class of the refuge from sandy loam to silt loam [15].

5.2.2. Bulk density: Fly ash addition generally decreased the bulk density of soils, which in turn

improved soil porosity and workability and enhanced water retention capacity [3] The water holding

capacity of sandy/loamy soils increased by 8% due to fly ash amendment [18], and accompanied an

increase in hydraulic conductivity helped in reducing surface encrustation.

5.2.3. Water-holding capacity: Fly ash increases the water retention capacity of soils because it causes

structural and textural changes. The capacity of the soil to hold water is related to the surface area, pore

space volume and continuity of pore space [19]. The low bulk density and thus higher porosity of Fly

ash help to create more pore space in the soil. The dominance of silt-size hollow particles creates a larger

hydrophilic surface area to hold water molecules [20]. Pathan [21] noticed an increase from 14% to 33%

of soil water content in the FA-amended soil when compared with non-amended soil. This property is

beneficial to soils, especially under rain-fed agriculture.

5.2.4. Soil pH: The extremely acidic or alkaline soils are supplemented with additives having pH

buffering capacity to bring their pH to neutral to maximize the nutrient availability. FA, which can be

acidic or alkaline depending on the source, can be used as a soil buffering agent for such problematic

soils [10]. The hydroxide and carbonate salts give fly-ash one of its principal beneficial chemical

characteristics, the ability to neutralize acidity in soils [15]. Fly-ash has been shown to act as a liming

material to neutralize soil acidity and provide plant-available nutrients [22]. Most of the fly-ash

produced in India is alkaline in nature; hence, its application to agricultural soils could increase the soil

pH and thereby neutralize acidic soils. Researchers have shown that the use of fly-ash as liming agent

in acid soils may improve soil properties and increase crop yield [23].

5.2.5. Fly-ash as a nutrient source to plants: As the fly ash is the reservoir of essential minerals, it

provides micro-nutrients like iron (Fe), zinc (Zn), copper (Cu), molybdenum (Mo), and boron (B,) and

macro nutrients like potassium (K), phosphorus (P) and calcium (Ca) [24]. Fly ash has also been used

as an adsorbent for reducing solubility of excessive phosphorus in the soil solution [25]. Chemically,

fly-ash contains elements like Ca, Fe, Mg (magnesium), and K, essential to plant growth, but also other

elements such as B, Se, and Mo and metals that can be toxic to the plants. Lime in fly-ash readily reacts

with acidic components in soil leading to release of nutrients such as S, B and Mo in the form and

amount favorable to crop plants [26]. Yu and his associates conducted a meta-analysis on effect of fly-

ash on plant biomass and found plant biomass was increased by fly ash application by 11.6–29.2% at

lower application rates (i.e. <25% of soil mass), and decreased by 45.8% at higher application rates (i.e.

50–100%)due to toxicity of heavy metals [27].

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 918

!

5.3(Fly Ash Utilization with Special Reference to Geotechnical Engineering:

5.3.1. Fly Ash mix as a replacement for earthen/sand backfilling: A well-proportioned mix of water,

portland cement, fly ash if needed some coarse and fine aggregates also called as a flowable fill can be

effective as a replacement for earthen backfills especially in small spaces like behind abutment walls,

basement walls, retaining walls (Figure 3). The suitability of flowable fill in such cases is due to its self-

compacting and self-leveling nature apart from increased strength. This material is also called a lean

mix backfill, flowable fly ash, controllable density fill. Considering the costs associated with

transporting, placing, and compacting of earthen backfill materials, this method of using flowable fill

not only provides an economical alternative but also increased strength and less maintenance. The

potential savings can be higher if the fly ash source is closer to the project location. Depending on the

project requirements, a flowable mix can be a high fly ash content or low fly ash one. The strength of

flowable fill directly depends on the quantity of cementitious material present, usually, the Class C based

fly ash flowable fill has more strength as compared to Class F based fly ash flowable fill owing to the

high CaO content of the former one.

Figure 3: Bridge abutment backfill with flowable fill (Courtesy: ACAA [28]).

5.3.2. Fly Ash Utilization in Fills/Embankments: While designing a fill/embankment, fly ash mixed with

other materials if properly proportioned, placed and compacted can provide for an economical

alternative to the engineered soil fills (Figure 4). However, a close control has to be ensured on moisture

content and particle size distribution. Typically silo-based fly ash is preferred over ponded fly ash

because of a better quality of the former. Before designing a fill/embankment comprehensive subsurface

evaluation has to be done, it should importantly include details about water table depth, shear strength

and compressibility characteristics of the foundation soil. The behavior of embankment typically

depends on the particle size distribution, compressibility, frost susceptibility and shear strength which

is why laboratory investigations of fly ash properties are important. Frost's susceptibility is often

considered a problem and this can be avoided by using a geotextile layer at the base to ensure seepage

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 919

!

cut-off. According to the CEA 2018-19 report a total of 31.30 million-ton of fly ash was used in

roads/embankments which constituted 14.42 % of total fly ash generation [8].

Figure 4: Fly Ash Utilization in Fills/Embankments (Courtesy: ACAA [28])

5.3.3. Fly Ash for stabilization of expansive soils: Many soils due to their mineral composition are very

much susceptible to volume changes owing to changes in moisture content. These volume changes result

in the failure of structures due to excessive settlements. Plasticity of soil is considered the primary factor

governing volume changes and higher the plasticity index of soil more is the likelihood of soil to undergo

volume changes. Fly Ash when mixed with such a soil results in a subsequent decrease of plasticity and

also reduced volume changes, the basic mechanism behind this is the change in the size of soil grains

i.e., a grain size transition occurs from clay size to silt size primarily due to the presence of quick lime

in fly ash. In simple terms fly ash cements the soil grains together and hence soil particle movements

are restricted. Usually, the addition rates range from 12 to 15 percent.

Conclusion

Considering the ever-increasing energy demands all around the world It seems that coal-based electricity

generation will see an increase in corning years especially in developing countries like India and

consequently more generation of fly ash is expected Thus fly ash generation is problematic keeping in

view the issues associated with area requirements for proper disposal and also deleterious impact on the

environment. As of now, in India, 77.59 percent of total fly ash generated is utilized in multiple areas.

However, the focus should be on 100 percent utilization keeping in mind above mentioned potential

uses of fly ash to the construction sector, agriculture, and industrial area. It’s imperative for governments

as well as individuals to make maximum use of fly ash in various areas so as to lessen the Influence of

fly ash not only on the environment but also on the economy Also. There is great scope in exploring

potential usage areas of fly ash apart from the above-mentioned one.

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 920

!

References

1.! S. J. Ahn, D. Graczyk, Understanding energy challenges in India. Policies, Players and Issues,

International Energy Agency (IEA), 2012.

2.! S. Kumar, G. Mucsi, F. Kristály, P. Pekker, Mechanical activation of fly ash and its influence on

micro and nano-structural behaviour of resulting geopolymers, Adv. Powd. Tech. 28 (2017) 805-

813. https://doi.org/10.1016/j.apt.2016.11.027

3.! L. C. Ram, R. E. Masto, Fly ash for soil amelioration: a review on the influence of ash blending

with inorganic and organic amendments, Earth Sci. Rev. 128 (2014) 52-74.

https://doi.org/10.1016/j.earscirev.2013.10.003

4.! S. A. Haldive, A. R. Kambekar, Experimental study on combined effect of fly ash and pond ash

on strength and durability of concrete, Int. J. Sci. Eng. Res. 4 (2013) 81-86.

5.! V. C. Pandey, N. Singh, Impact of fly ash incorporation in soil systems, Agr. Eco. Environ. 136

(2010) 16-27. https://doi.org/10.1016/j.agee.2009.11.013

6.! M. L. D. Jayaranjan, E. D. Van Hullebusch, A. P. Annachhatre, Reuse options for coal fired power

plant bottom ash and fly ash, Rev. Environ. Sci. Biotech. 13 (2014) 467-486.

https://doi.org/10.1007/s11157-014-9336-4

7.! MOEF, Gazette notification for Ministry of Environment and Forests, no. 563. New Delhi:

Ministry of Environment and Forests, 14 September 1999.

8.! CEA: Central Electricity Authority Report 2018-2019. Available online at:

http://cea.nic.in/reports/others/thermal/tcd/flyash_201819.pdf (accessed on 05-04-2020).

9.! M. Ahmaruzzaman, A review on the utilization of fly ash, Prog. Ener. Comb. Sci. 36 (2010) 327-

363. https://doi.org/10.1016/j.pecs.2009.11.003

10.!Z. T. Yao, X. S. Ji, P. K., Sarker, J. H. Tang, L. Q. Ge, M. S. Xia, Y. Q. Xi, A comprehensive

review on the applications of coal fly ash, Eart. Sci. Rev. 141 (2015) 105-121.

https://doi.org/10.1016/j.earscirev.2014.11.016

11.!N. S. Pandian, K. C. Krishna, B. Leelavathamma, Effect of fly ash on the CBR behaviour of

soils. Indian Geotechnical Conference, Allahabad 1 (2002) 183-186.

12.!R. W. Talbot, M. A. Anderson, A. W Andren, Qualitative model of heterogeneous equilibriums in

a fly ash pond, Environ. Sci. Tech. 12 (1978) 1056-1062. https://doi.org/10.1021/es60145a001

13.!W. R. Roy, R. A. Griffin, Illinois basin coal fly ashes. 2. Equilibria relationships and qualitative

modeling of ash-water reactions, Environ. Sci. Tech. 18 (1984) 739-742.

https://doi.org/10.1021/es00128a004

14.!D. Shen, W. Wang, Q. Li, P. Yao, G. Jiang, Early-age behaviour and cracking potential of fly ash

concrete under restrained condition, Mag. Conc. Res. 72(5) (2020) 246-261.!

https://doi.org/10.1680/jmacr.18.00106

15.!M. Basu, M. Pande, P. B. S. Bhadoria, S. C. Mahapatra, Potential fly-ash utilization in agriculture:

a global review, Prog. Nat. Sci. 19(2009) 1173-1186. https://doi.org/10.1016/j.pnsc.2008.12.006

16.!A. Bhatt, S. Priyadarshini, A. A. Mohanakrishnan, A. Abri, M. Sattler, S. Techapaphawit, Physical,

chemical, and geotechnical properties of coal fly ash: A global review, Case Studies in

Construction Materials 11 (2019) e00263.!https://doi.org/10.1016/j.cscm.2019.e00263

Yousuf et al., J. Mater. Environ. Sci., 2020, 11(6), pp. 911-921 921

!

17.!J. Weber, S. Strączyńska, A. Kocowicz, M. Gilewska, A. Bogacz, M. Gwiżdż, M. Debicka,

Properties of soil materials derived from fly ash 11 years after revegetation of post-mining

excavation, Catena 133 (2015) 250-254. https://doi.org/10.1016/j.catena.2015.05.016

18.!A. Tejasvi, S. Kumar, Impact of fly ash on soil properties. Nat Acad. Sci. Lett. 35 (2012) 13-16.

https://doi.org/10.1007/s40009-011-0002-x

19.!R. B. Panda, T. Biswal, Impact of Fly Ash on Soil Properties and Productivity. Int. J. Agr. Environ.

Biotech. 11 (2018) 275-283. DOI: 10.30954/0974-1712.04.2018.8

20.!J. Skousen, J. E. Yang, J. S. Lee, P. Ziemkiewicz, Review of fly ash as a soil amendment. Geosys.

Eng. 16 (2013) 249-256. https://doi.org/10.1080/12269328.2013.832403

21.!S. Pathan, Fly ash amendment of sandy soils to improve water and nutrient use in Turf. Ph. D.

Thesis in Agriculture and Plant Sciences, University of Western Australia, 2003.

22.!K. Komonweeraket, B. Cetin, A. H. Aydilek, C. H. Benson, T. B. Edil, Effects of pH on the

leaching mechanisms of elements from fly ash mixed soils, Fuel. 140 (2015) 788-802.

https://doi.org/10.1016/j.fuel.2014.09.068

23.!Y.J. Feng, F. Li, X. L. Wang, Principal chemical properties of artificial soil composed of fly ash

and furfural residue, J Pedosph. 16 (2006) 668–672. https://doi.org/10.1016/S1002-

0160(06)60101-X

24.!A. Malik, A. Thapliyal, Eco-friendly fly ash utilization: potential for land application. Critic. Rev.

Environ. Sci. Tech. 39(4) (2009) 333-366. https://doi.org/10.1080/10643380701413690!

25.!H. He, Z. Dong, Q. Peng, X. Wang, C. Fan, X. Zhang, Impacts of coal fly ash on plant growth and

accumulation of essential nutrients and trace elements by alfalfa (Medicago sativa) grown in a

loessial soil, J. Environ. Manag. 197(2017) 428-439.

https://doi.org/10.1016/j.jenvman.2017.04.028

26.!H. P. Jambhulkar, S. M. S. Shaikh, M. S. Kumar, Fly ash toxicity, emerging issues and possible

implications for its exploitation in agriculture; Indian scenario: A review, Chemosph. 213 (2018)

333-344. https://doi.org/10.1016/j.chemosphere.2018.09.045

27.!C. L. Yu, Q. Deng, S. Jian, J. Li, E. K. Dzantor, D. Hui, Effects of fly ash application on plant

biomass and element accumulations: a meta-analysis, Environ. Pollut. 250 (2019) 137-142.

https://doi.org/10.1016/j.envpol.2019.04.013

28.!ACAA (America Coal Ash Association), Fly Ash facts for Highway Engineers, 2003. Available

online at: https://www.fhwa.dot.gov/pavement/recycling/fafacts.pdf (Accessed on 05-04-2020).

(2020) ; http://www.jmaterenvironsci.com/index.html